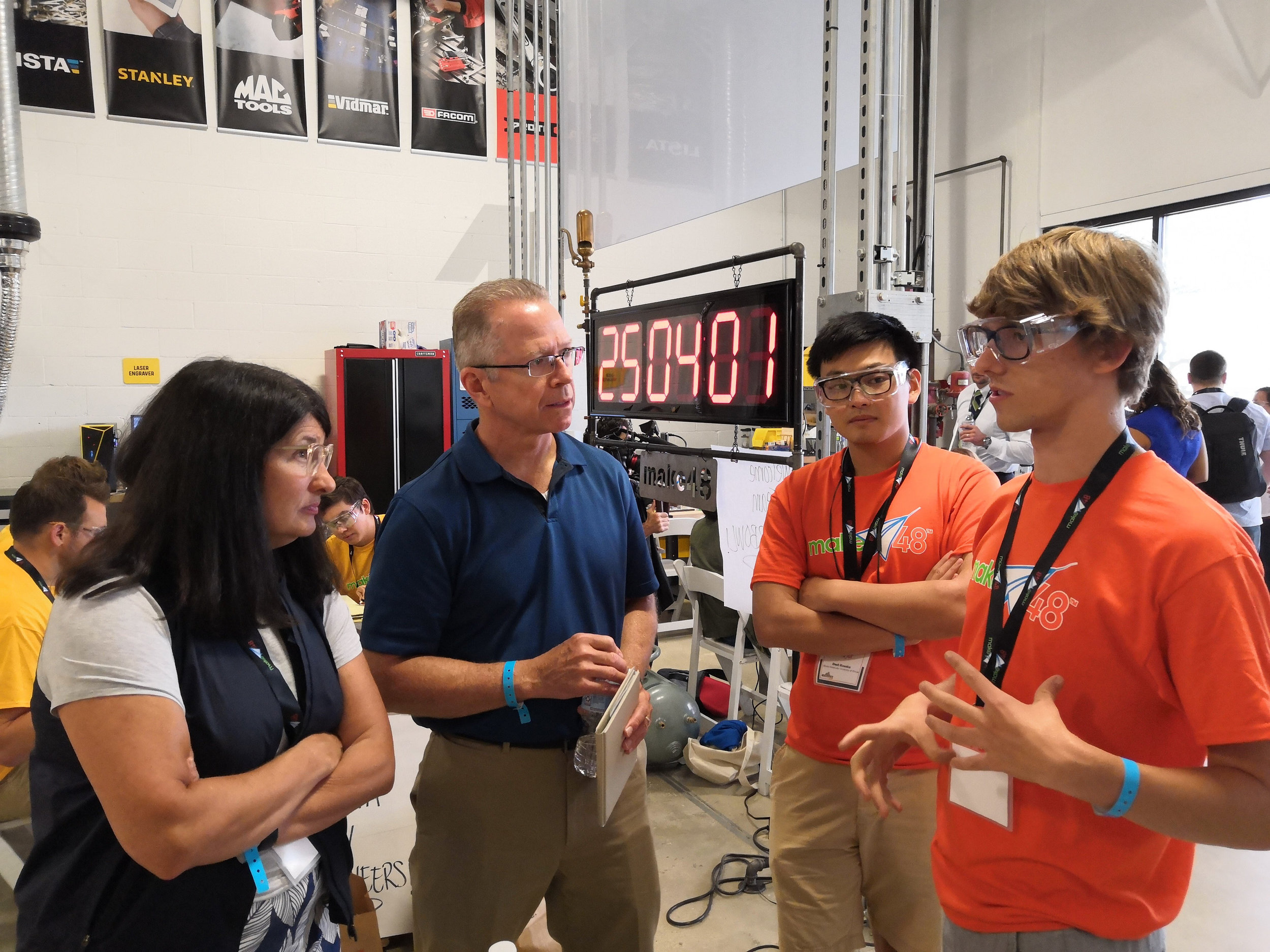

Illinois MakerLab Team Competes in National Make48 Competition

/This year, the University of Illinois was one of the twelve schools invited to participate in Make48, an annual competition that invites teams of four individuals to participate in a weekend-long design competition. Participants must plan, prototype, and pitch a new idea, drawing inspiration from a given theme in just 48 hours! This year we were excited to send a team of 4 from the MakerLab: Yuxuan Tang, Dashiell Kosaka, Suixin Liu, and William Casey Jones. They got to travel to Baltimore, Maryland this past August to engage with makers from all around the country. And the best part? They were filmed lived as Make48 doubles as an educational tv series. So, our very own team will appear on season 3 which will air Fall 2019! Stay tuned and don’t watch our makers in action at Make48 next fall!

“I learned so much ranging from shop tools to marketing, knowledge that my major would never have given me alone. I knew being an entrepreneur was hard, but even with the constant assistance from the helpers there, we were very pressed for time. There were also so many sponsors and big names for the event we were able to meet [and] the team was able to get our names out there.”

Stay tuned for MakerLab updates by subscribing to our newsletter, liking us on Facebook, or following us on Snapchat(uimakerlab), Twitter or Instagram. Need a bulk order of your item printed? Contact us and we will help you get started!

The University of Southern California is testing a giant 3D printer that could be used to build a whole house in under 24 hours.

The University of Southern California is testing a giant 3D printer that could be used to build a whole house in under 24 hours.