Making Things Class Develops Prototypes

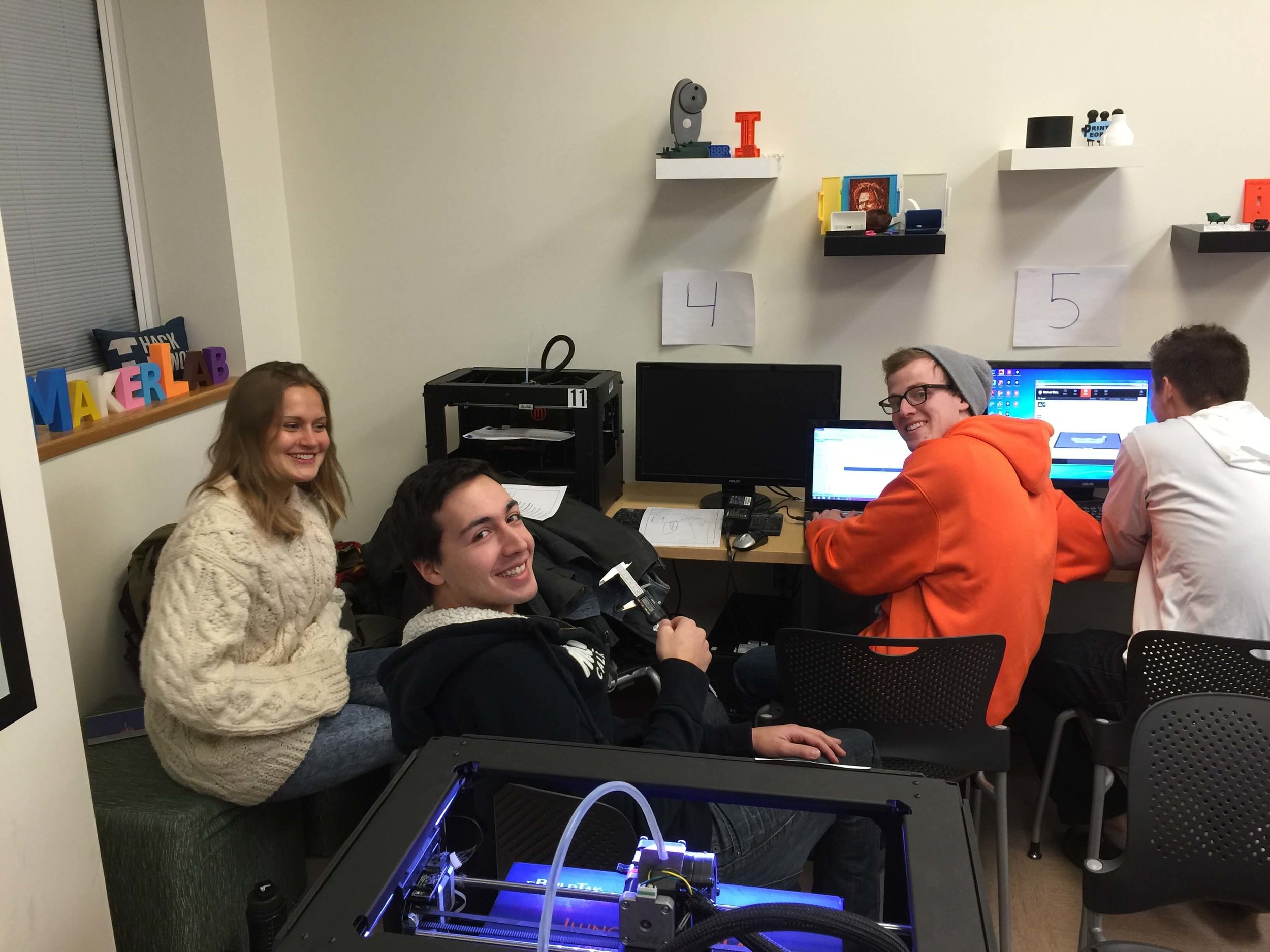

/In last week's Making Things class, we focused on refining the prototypes for our products. Our team (Handmad3) is creating multiPLY, a bathroom aid that increases the capacity of your toilet paper holder. We finished prototyping, so we focused on other details, such as developing the instruction sheet that will come with the product. We also started working on our product's packaging, slogan, and distribution. So, in essence, we are working on our marketing plan. We will use Facebook, Square, and Instragram as tools for our marketing efforts. Our goal now that we have finished our prototype is to build an inventory. Having an inventory will allow us to begin selling quickly, as well as have a better presentation when we sell in person. We are therefore trying to print as many products as possible.

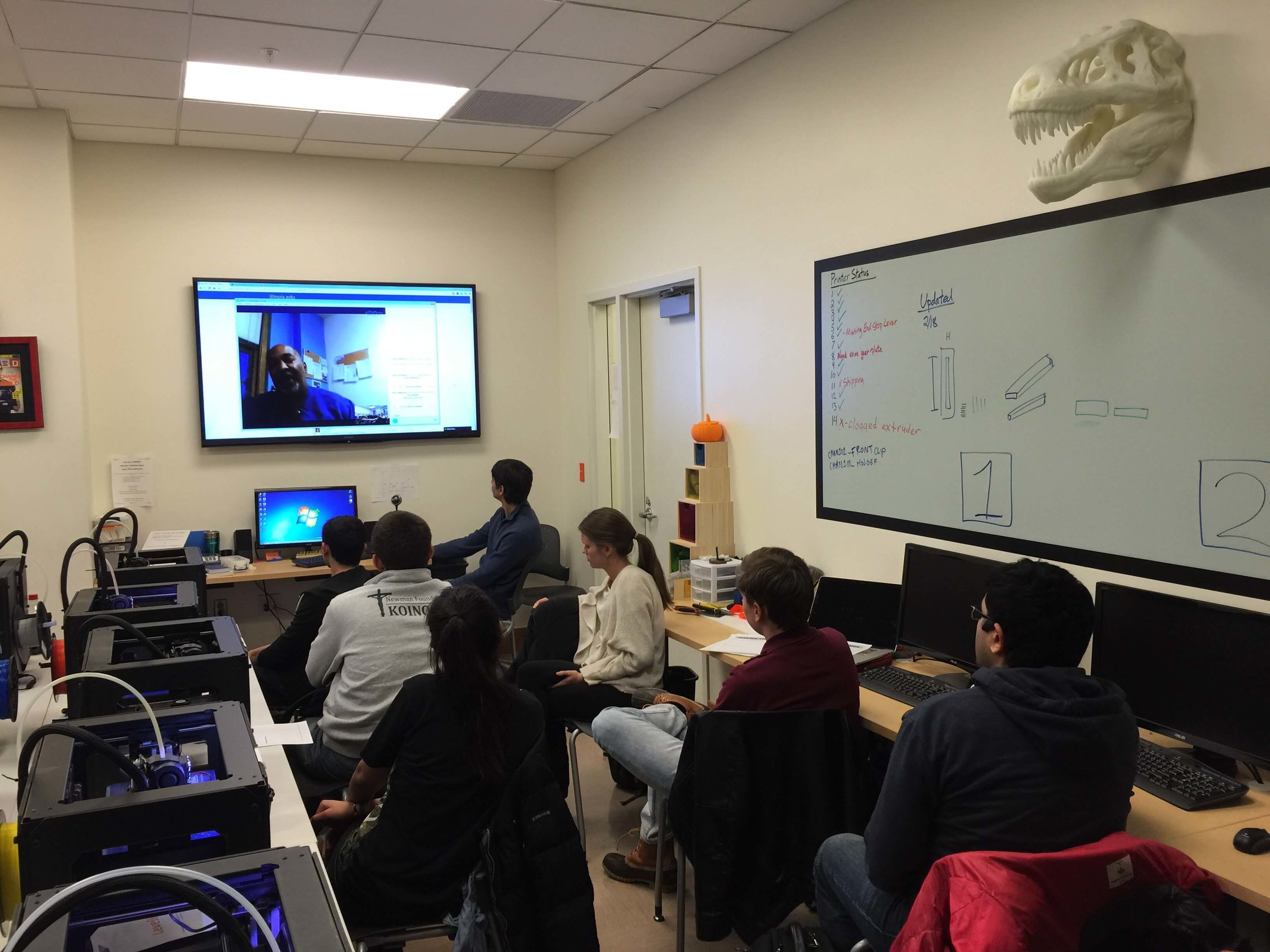

This week's class had another guest speaker, Eli Share from Dremel. He spoke about his company’s use and distribution of 3D printers, including their new consumer-level model intended for the casual user. He also discussed his vision for how additive manufacturing will evolve in the future: the ecosystem of 3D printing will change, but the hardware will plateau.

We also ate Rosati’s pizza and listened to the musical stylings of James Taylor and Bob Marley.

By Team Handmad3

Find out more about whats happening at the Making Things Class 2015. Stay tuned for updates by subscribing to our blog feed, or just get our posts via email(subscribe on the right navigation). You can also like us on Facebook or follow us on twitter to stay updated.