Making wood from .....

/Gabe Tavas, a freshman in Industrial Design, and founder of Novel Printers, first began his venture in order to explore the idea between maintaining regular use of wood while still preserving the ecosystem. Gabe wanted to figure out a way to use 3D bioprinters to make commercial wood without the need of actually cutting down a tree. After prototyping with printers from MakerLab and Community Fab Lab, he entered Future of the Forests Xprize. This is a global competition which focused on using technology to improve our current situation around deforestation and eventually ended up winning a prize!

Here is the story of how Gabe got started, in his own words:

Growing up in Chicago, I had the benefit of being immersed in two different settings: the forest and the workshop. One was teeming with life and nature’s ingenuity, and the other hummed with machinery and human creativity. On first glance, the two seem completely incompatible. Wood, for example, is a material that nature makes and humans either use or waste. In 2018 alone, enough trees to cover all of Belgium were lost to deforestation in countries like Brazil and Indonesia to make room for agricultural land and harvest valuable timber. In the workshop, some of this timber is highly prized for its structures, colors, and patterns. In the forest though, losing that many trees so quickly threatens to ruin the local environments and exacerbate climate change. So when I began my venture, Novel Printers, in October 2018, I wondered if there was a way to still support human craftsmanship while preserving the ecosystems that make it possible in the first place.

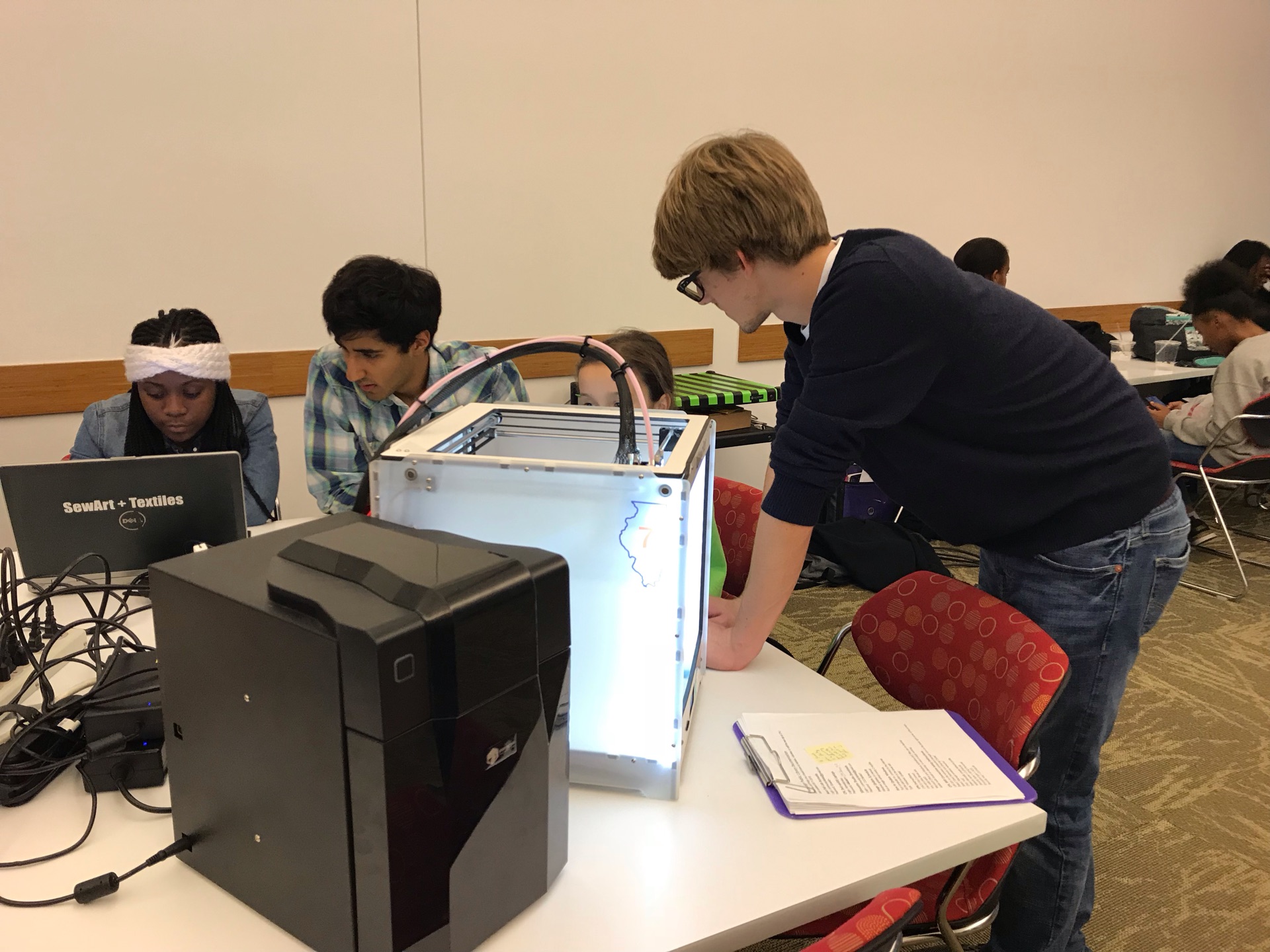

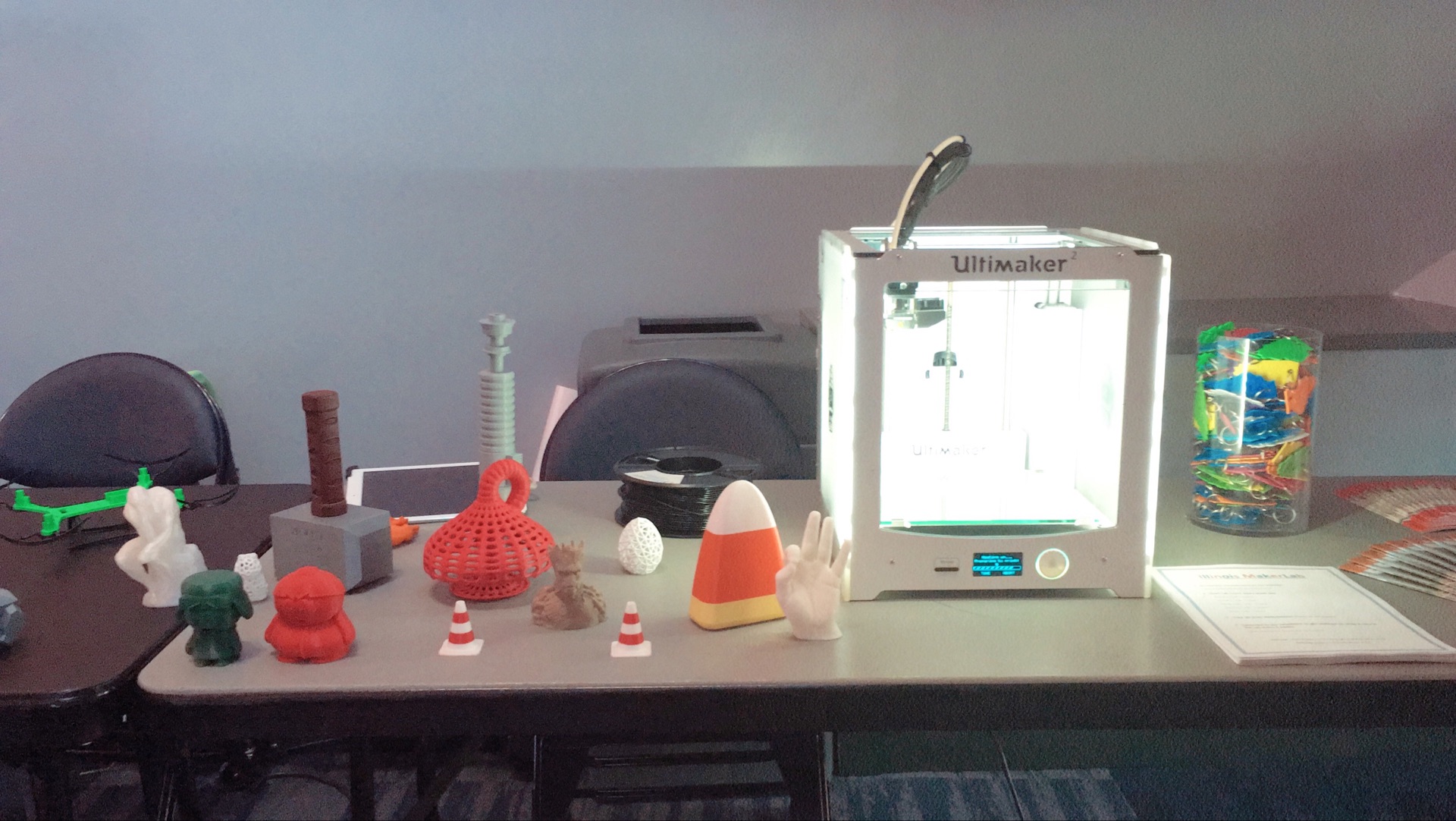

At first, I presented this line of thinking to an audience of about 100-200 people attending 54, a weekend-long event run by an organization called Founders that helps student entrepreneurs form teams for startup ventures. In my case, I wanted to figure out a way to use 3D bioprinters to make commercial wood from the ground up without harming any trees, which would allow them to slowly recover from human lumbering. One thing led to another, and I teamed up with a few engineering students before reaching out to the Illinois Makerlab to borrow an older 3D printer and convert it into a bioprinter with retraction abilities that can extrude cellulose acetate — a derivative of the cellulose found in wood — dissolved in acetone.

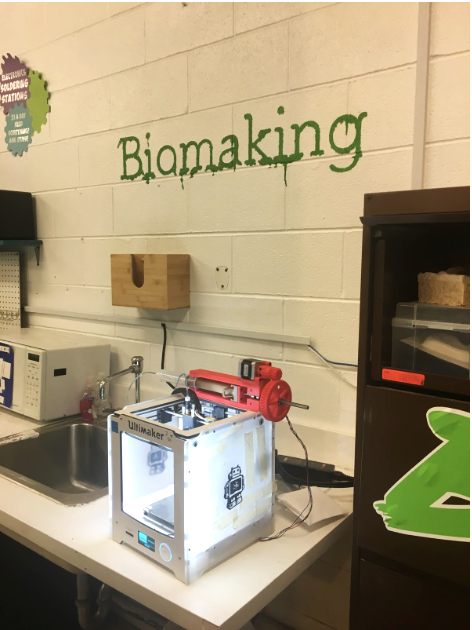

After three months of trial and error, we not only succeeded in the conversion but also secured a small workspace for the bioprinter in the Community Fab Lab where we could conduct more research as well as share our work with visitors. Even before we moved in though, I was fascinated with the Fab Lab’s biomaking tools, which some people used to grow bowls of mycelium mushroom — an eco-friendly alternative to styrofoam packaging — and analyze small samples of DNA. As I worked more and more in the Fab Lab, I realized that, although I had been able to print simple objects with cellulose acetate, biomaking could allow me to achieve better results with materials that — unlike acetate — are not created with hazardous chemicals like sulfuric acid. Ultimately, what I really had to do was take a hint from nature and find a way to shape and refine cellulose without any toxic downsides.

Soon enough, I was tinkering with cellulose grown by (slimy and stinky but otherwise harmless) bacteria. Since paper is made of cellulose that normally has to be extracted from trees with harmful chemicals and a large amount of energy, cellulose-producing bacteria can make a purer product more safely and easily at room temperature. In fact, while the bacterial paper I made started out brown and wrinkled, I eventually got it to the point of looking white and fairly even.

At the same time that Novel Printers was having some success with the paper prototypes, we also submitted an entry to the Future of the Forests Xprize, a global competition that sought to define the framework by which innovators in a future Xprize should develop technology that addresses deforestation. In total, the Xprize had six categories for six winning teams: decoupling land from food production, fighting deforestation, value of forests, renewable energy production, carbon sequestration, and alternative wood products. Out of over 200 total entries, we were selected as the winner of the alternative wood products category by a panel of judges and emerged as one of only two winning American teams. Now, the $2,500 prize money we received will be used to fund more research into bacterial cellulose and support more biomaking in the Fab Lab.

Thanks for sharing your story with us Gabe! We look forward to seeing what other great things you have in the future. If you want to get in touch with Gabe, send him an email at gtavas2 AT illinois DOT edu.

Stay tuned for MakerLab updates by subscribing to our newsletter, liking us on Facebook, or following us on Snapchat(uimakerlab), Twitter or Instagram. Have an event you want to host at the MakerLab? Contact us and we will help you get started!