Making Things Class Narrows Down Ideas

/ During last week’s Making Things Class, we discussed some tips for creating innovative products. One is to do the opposite, when everyone else is designing towards one direction, go towards the complete opposite way. Another is the principle of subtraction, where reducing certain features of a product can increase its value. For example the invention of stereo player replaced speakers with headphones, reducing its size to make it a portable device. Along with this invention came the need for headphones which didn’t exist before. The design of a new product can introduce a new need that didn’t yet exist.

During last week’s Making Things Class, we discussed some tips for creating innovative products. One is to do the opposite, when everyone else is designing towards one direction, go towards the complete opposite way. Another is the principle of subtraction, where reducing certain features of a product can increase its value. For example the invention of stereo player replaced speakers with headphones, reducing its size to make it a portable device. Along with this invention came the need for headphones which didn’t exist before. The design of a new product can introduce a new need that didn’t yet exist.

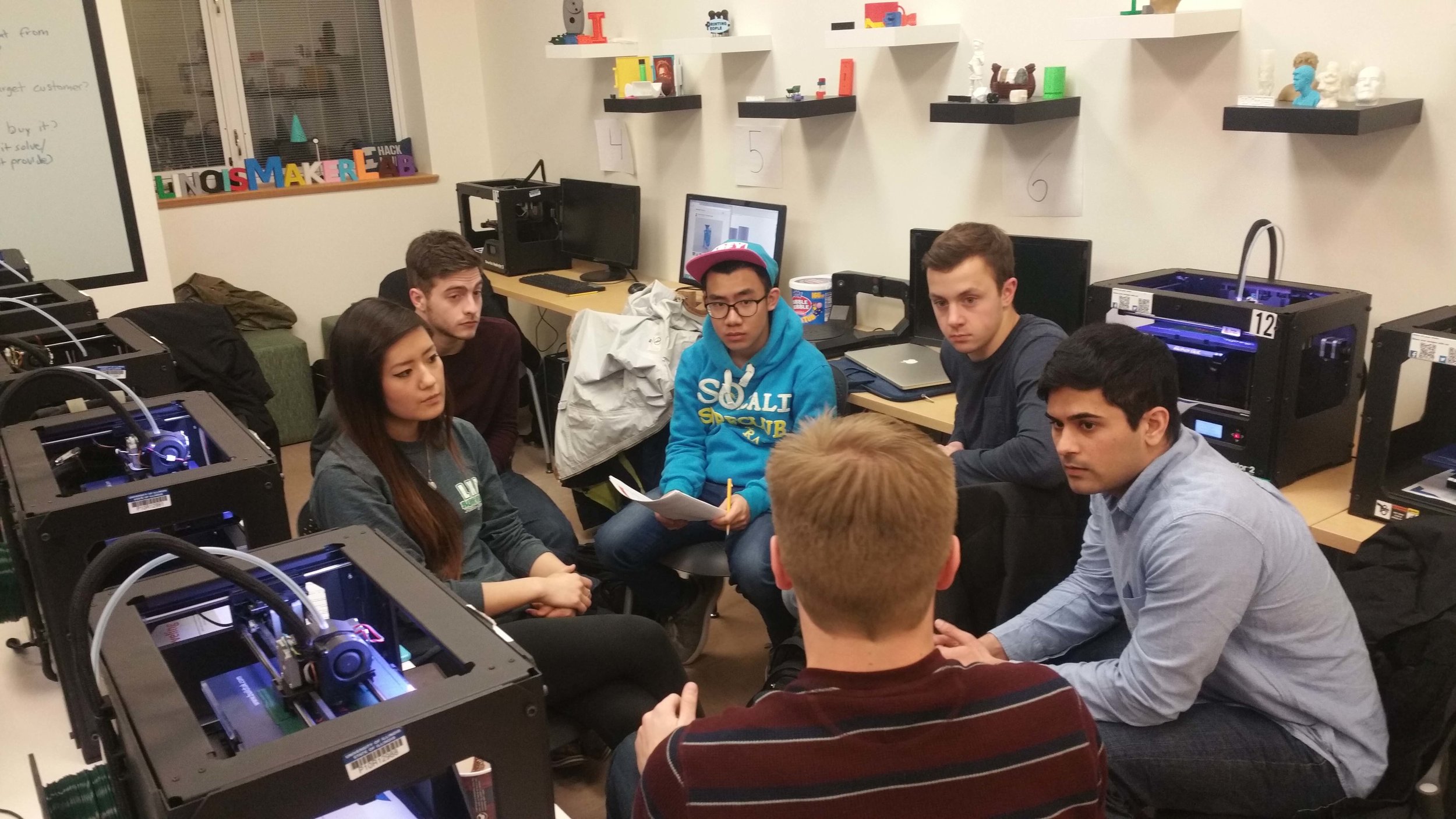

Each group then discussed their product ideas and evaluated three favorite ones based on their value propositions, target markets, competitors, required resources and challenges. Some ideas the groups came up with include: a sponge holder that can hang on side of the sink, an attachment to toothbrush that can divert water upward, a toilet paper holder that makes it easier to change toilet paper rolls. During the coming week, we will try to select our final concept!

By: Minion Makers

Find out more about whats happening at the Making Things Class 2015. Stay tuned for updates by subscribing to our blog feed, or just get our posts via email(subscribe on the right navigation). You can also like us on Facebook or follow us on twitter to stay updated.