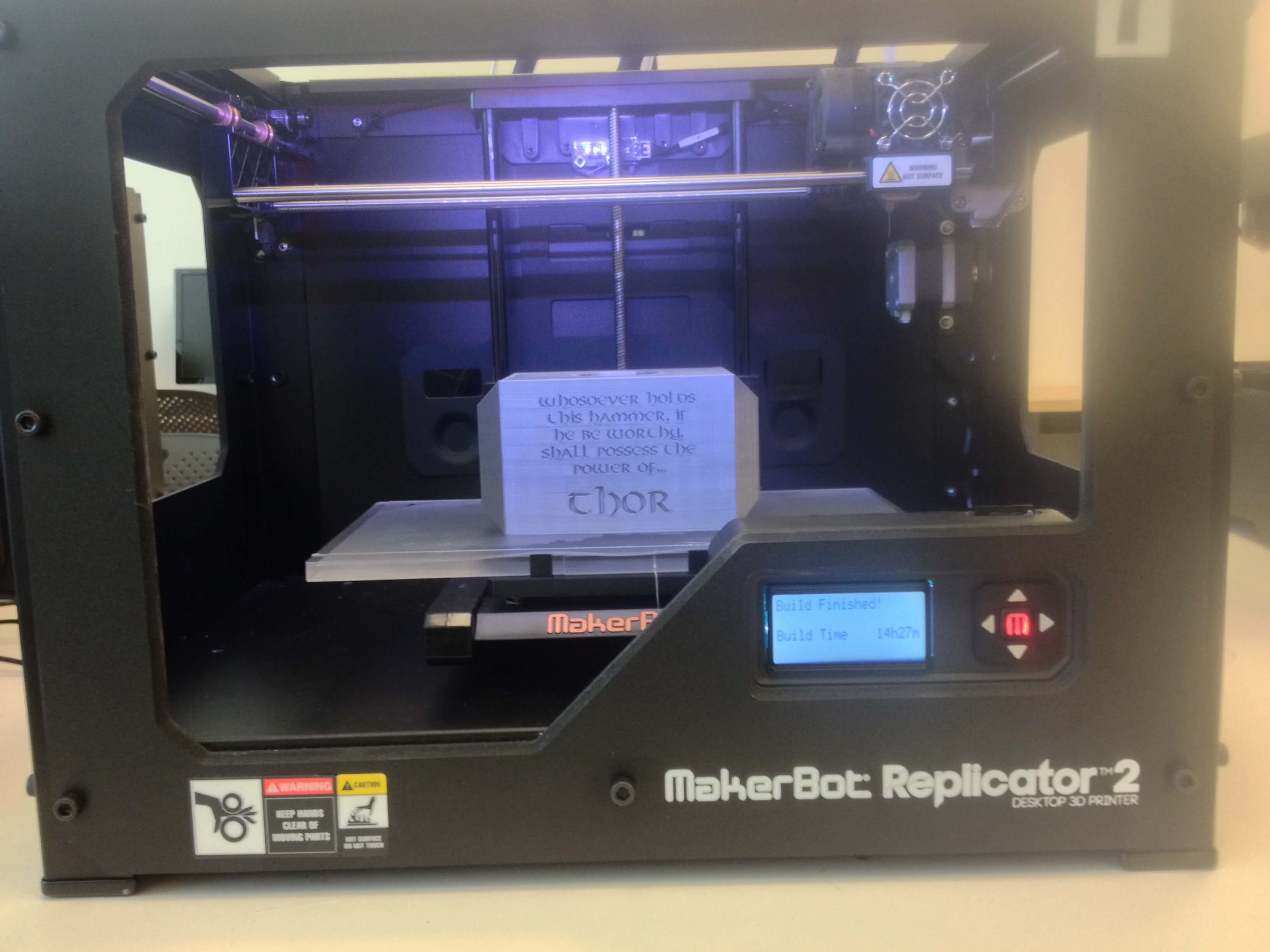

Earlier this month, one of our faculty members had a problem that is common to many of us: His 2D Printer stopped printing! Upon closer inspection, he realized that one of the small plastic guides above the paper tray was broken. Unfortunately, a replacement guide was not available from the manufacturer.

Normally, when this type of situation occurs, we would end up buying a new printer. However, in this case, our intrepid faculty member enlisted the help of the MakerLab. He gave one of our Gurus the broken guide, which the Guru then used to design a replacement part using 3D modeling software and then printed the newly designed replacement using one of our 3D printers. The entire process took less than one hour and the cost of the materials was about 10 cents. With the help of one of our highly skilled computer technicians, our faculty member was able to attach the newly printed guide and his 3D repaired 2D printer was back in business!

This is another great example of how 3D printing can extend the life of the things we own by enabling us to repair broken equipment rather than replacing it with something new. Why spend $250 for a new printer when you can repair it for less than 10 cents?

Our Professor's 2D Printer

The broken part is on the right and the newly created 3D replacement is on the left.

The installed 3D printer replacement part (on the left) .

Join the Maker movement at Illinois. Subscribe to our blog RSS feed to be the first to hear about events, new tutorials, and other exciting news from the MakerLab and Like our Facebook page.