Does the ability to customize design affect product adoption and satisfaction?

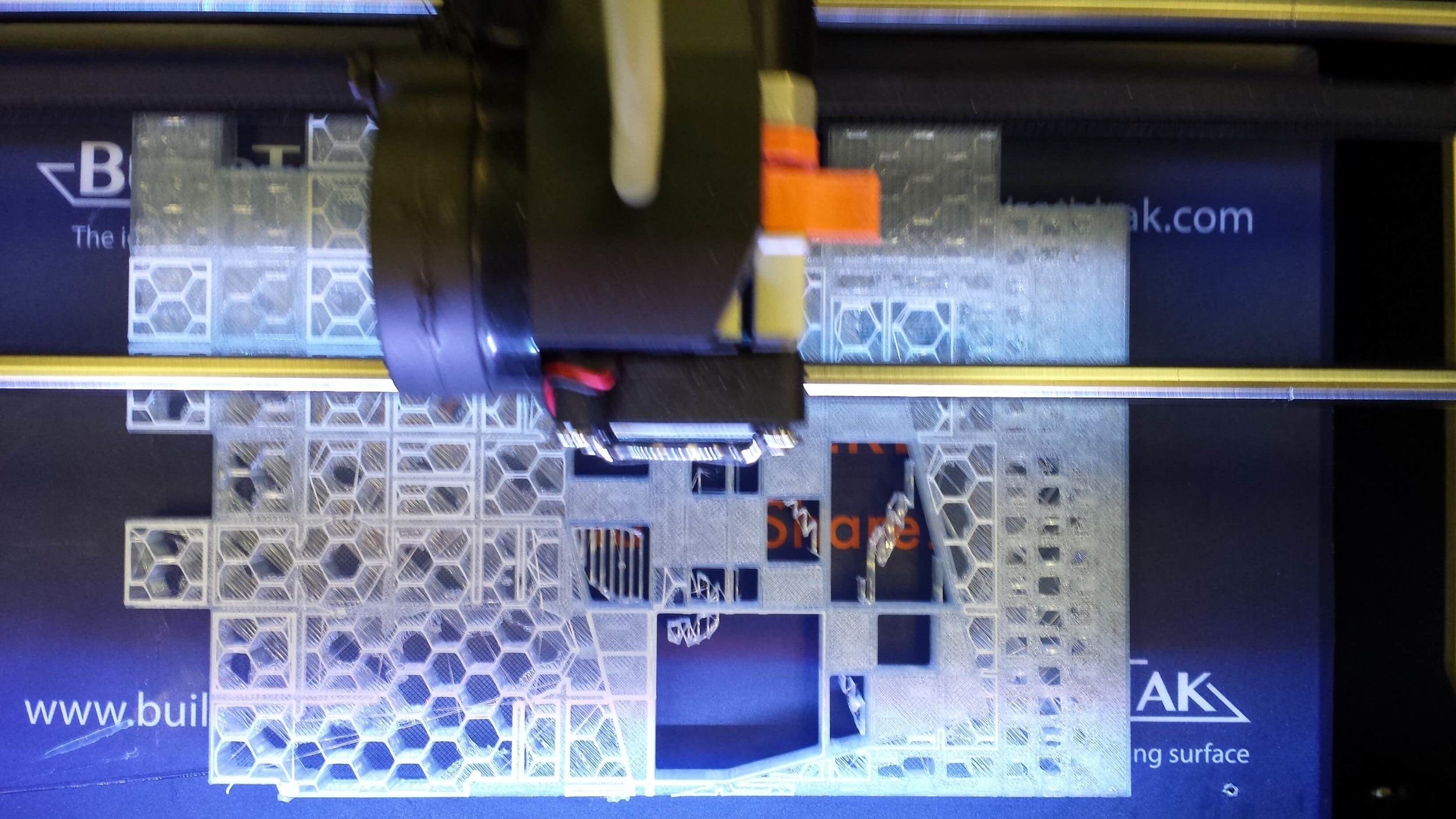

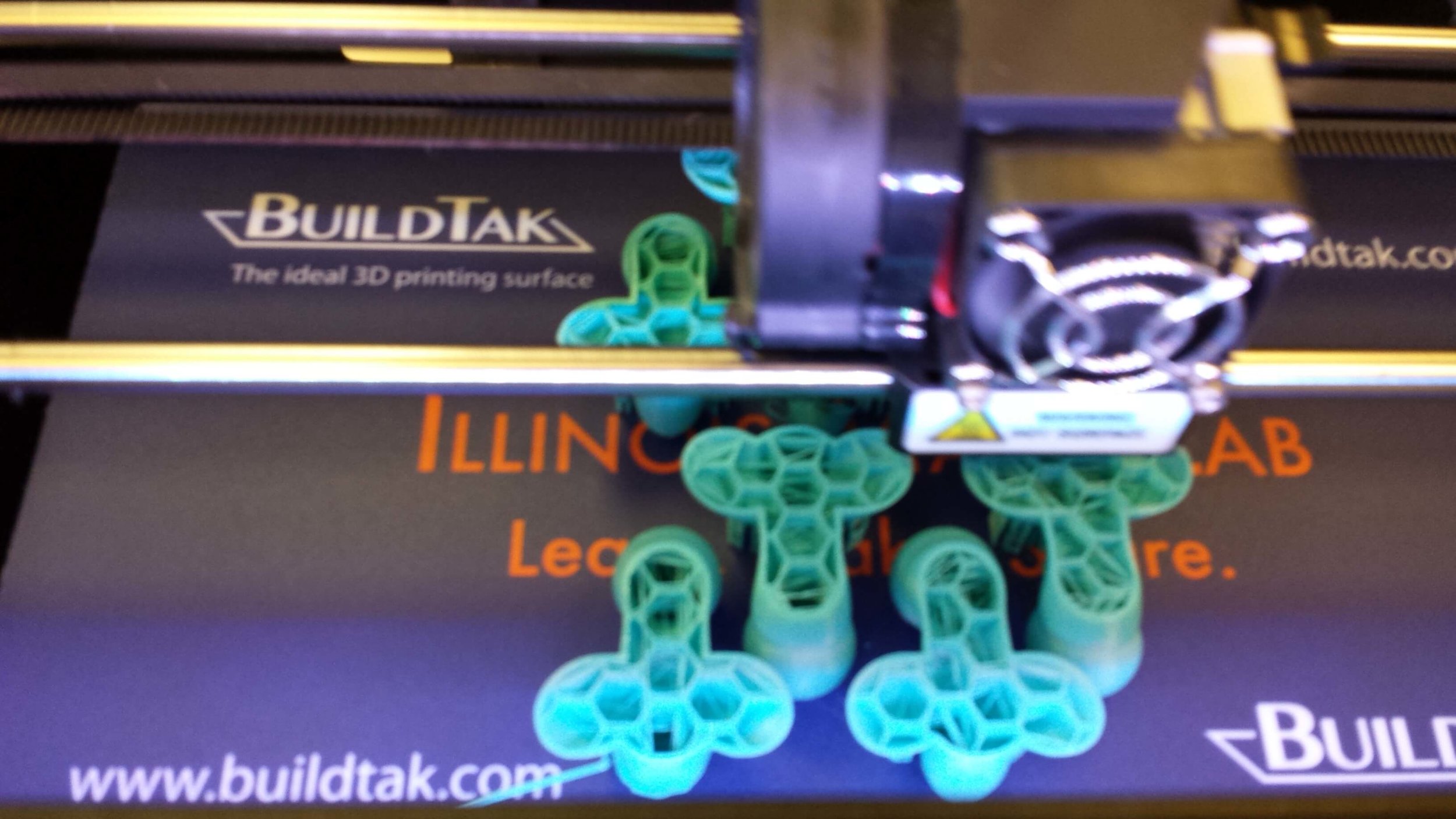

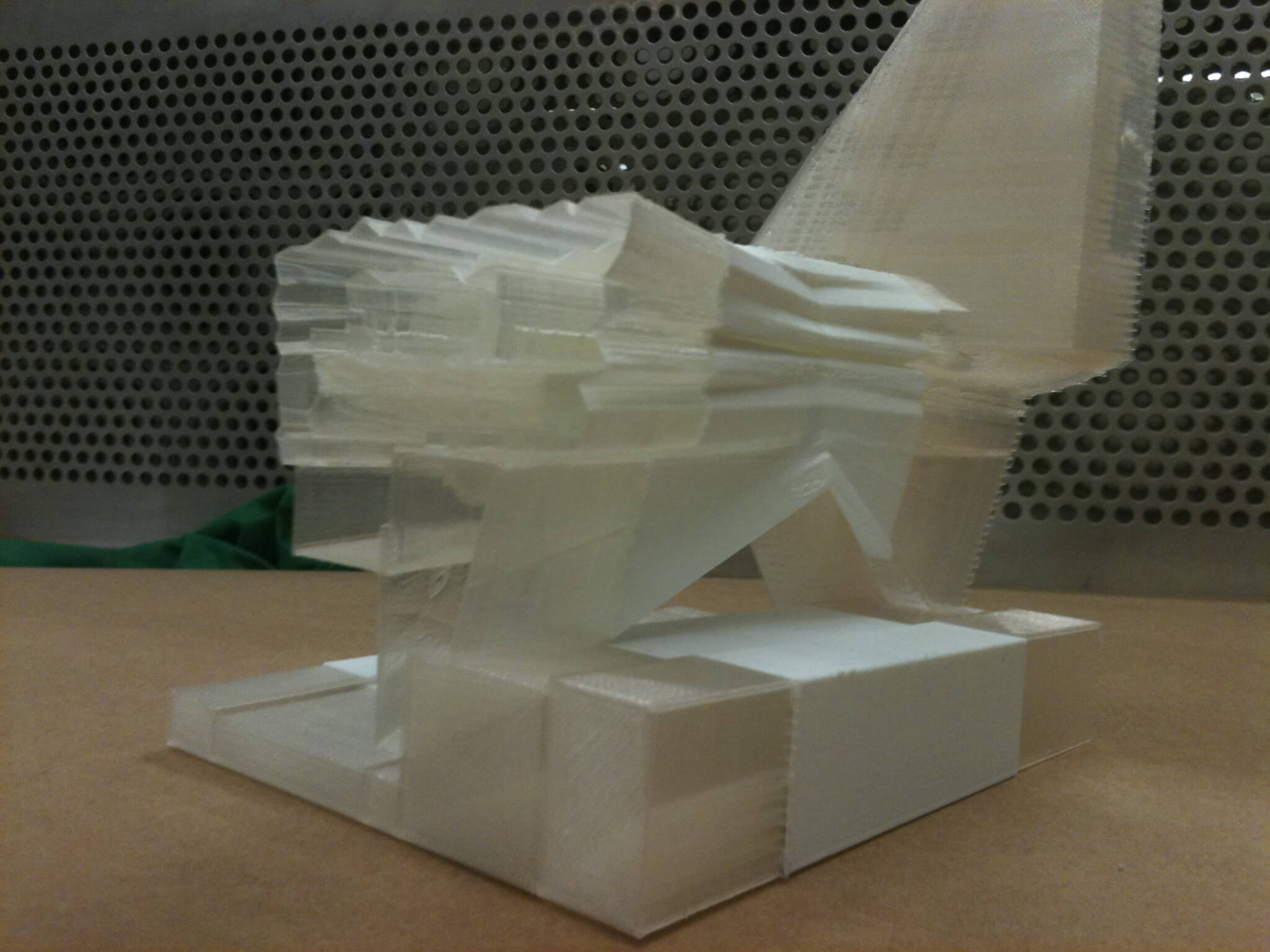

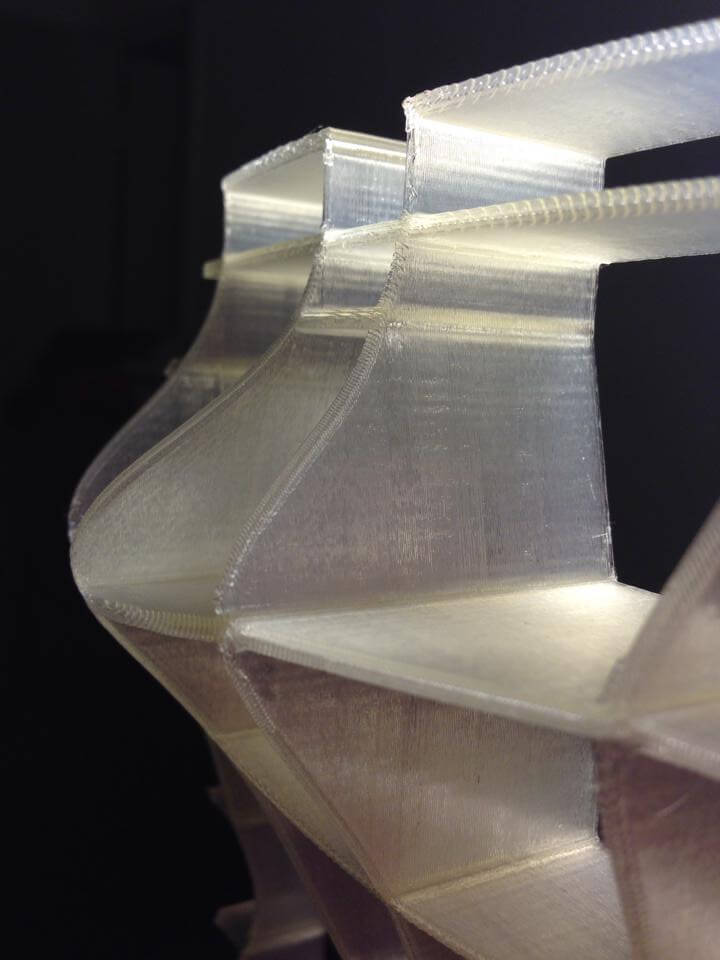

/This post is contributed by Greg Fisher, who conducted research on the question above, in partnership with the MakerLab. This post is part of our series on research at the lab, in addition to our initiatives in Education and Outreach. While the future applications of 3D printing technology continue to emerge, it is already apparent that 3D printing holds the ability to transform the way in which our society consumes products that organizations design for us to buy instead of making products for ourselves. During the spring semester, a dissertation research project utilized the Maker Lab to obtain unique insights about how modification of 3D printable product designs affects users’ sentiment of creating products, and how this sentiment of creation affects their likelihood of product adoption. Students who participated in this study were able to customize a digital design of a cell phone case to meet their unique preferences. As part of the study, participants were invited to the Maker Lab to 3D print their customized designs and receive their cases. Printing at the Maker Lab enabled students to experience the process of creating their own cell phone cases that they could keep and show to their friends. The students completed a brief post-print survey at the Maker Lab to measure the extent of their satisfaction with the product creation process as compared to the typical consumption process of buying a firm-designed product from a retailer. When asked to provide reasons why they did or did not like the experience, students reported comments such as “it was really cool to see it be created right before your eyes” and “I made it myself!”

The University of Southern California is testing a giant 3D printer that could be used to build a whole house in under 24 hours.

The University of Southern California is testing a giant 3D printer that could be used to build a whole house in under 24 hours.

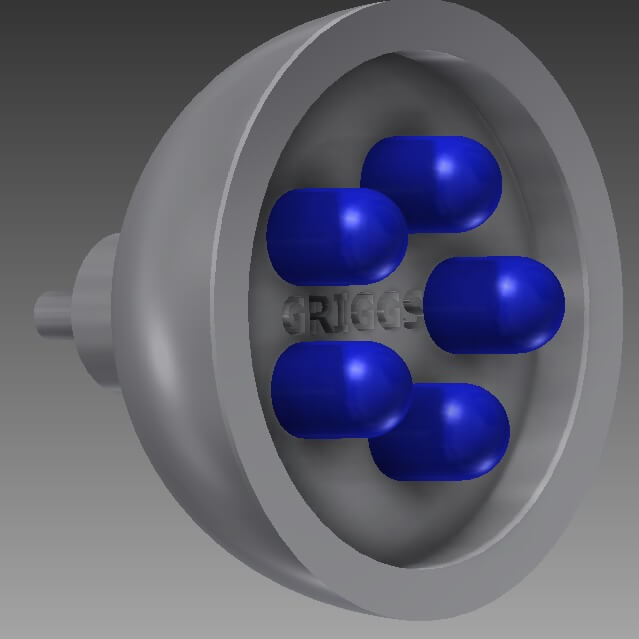

Professor Jeff Lowenstein (from the Organizational Behavior Group of the Department of Business Administration) recently used the MakerLab to fabricate a prototype of a LED lightbulb for use in class experiments this semester.

Professor Jeff Lowenstein (from the Organizational Behavior Group of the Department of Business Administration) recently used the MakerLab to fabricate a prototype of a LED lightbulb for use in class experiments this semester.