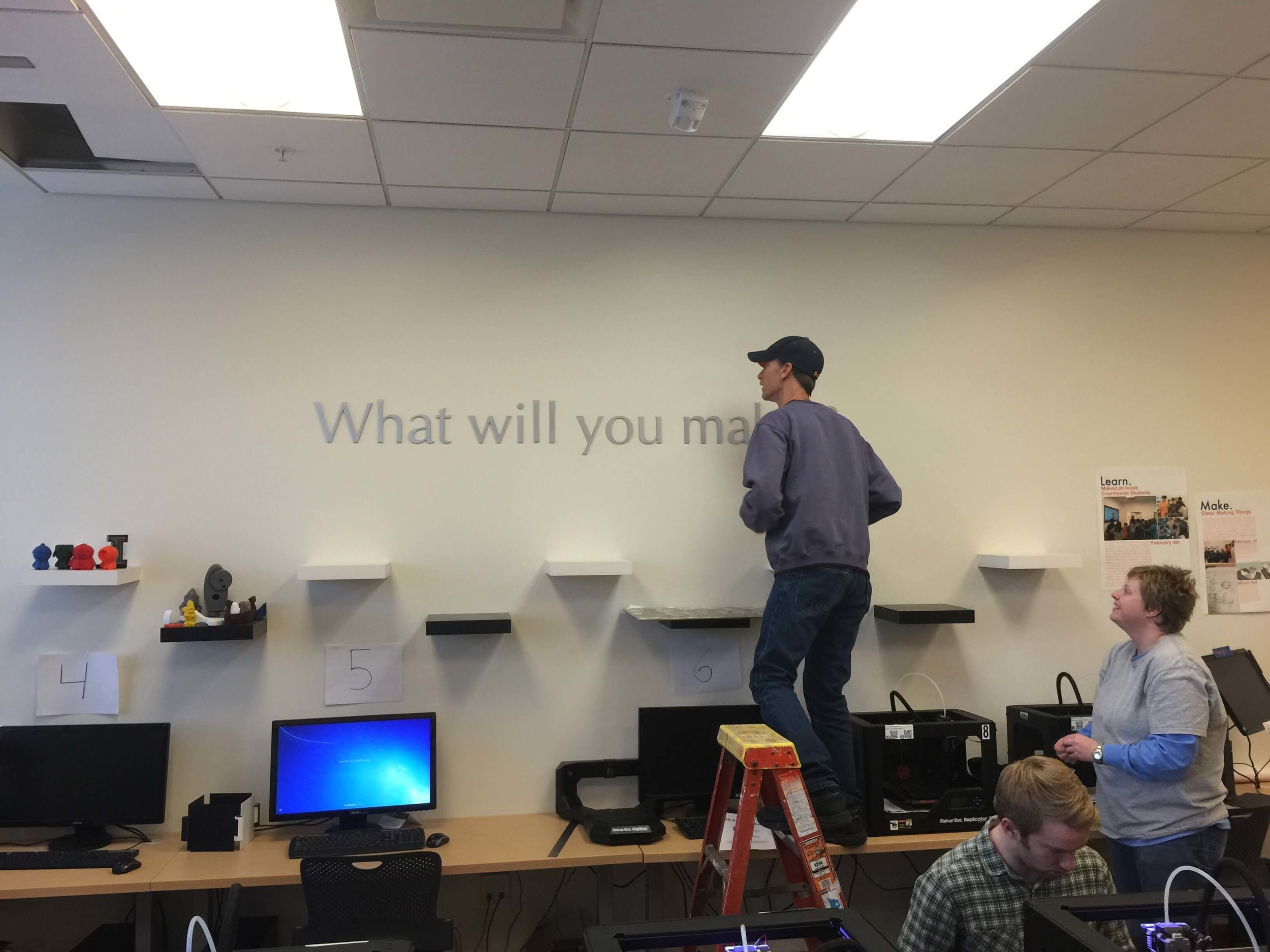

MakerLab gets New Signage!

/Earlier this week, our friends from the sign shop at Facilities and Services (F&S) stopped by the Lab to install our new sign. This sign reads, "What will you make?" and is posted on our main east wall. The message is simple: People visit our lab to make things that didn't exist before, are not made by firms, and cannot be bought in a store. What will you make? If you don't know the answer to this question, please stop by for some inspiration and helpful advice from our Gurus!

Make your own Gifts

/Christmas is the season of giving. The things that we give to our friends and family during the holiday season are typically bought in a store and manufactured in a distant land. 3D Printing disrupts this pattern by empowering individuals to make (rather than buy) gifts. There is no need to go to a store since the manufacturing can now be done on your desktop!

As an example of this self-manufactured gifts, one of our Makers printed this giant Lego figurine for his son. This figurine is composed of seven different parts, which are printed in blue, red and yellow. Just like a real Lego, the head, hands, and legs have full range of motion and can be disassembled. The finished product is shown inside one of the MakerLab's Replicator 2 printers to add a dramatic background!

If you had a 3D printer, what would you make as a gift? Try out some things from one of several collections on Thingiverse. If you don't own a 3D printer, no problem. You can stop by and use one of ours.

Meet the Maker: Katie Kinley

/The International Sustainable Electronics Competition is one which urges the industrialized world to move towards more green initiatives and develop a more sustainable system for the development, use and management of electronic devices. Katie Kinley entered this competition as a senior at the University of Illinois at Urbana-Champaign. After talking a friend whose job was to change the batteries for microphone packs in a large campus lecture hall, Katie came up with the idea of a Microphone Inductive Charger.

Although her idea did not place in the competition, the Illinois Sustainable Technology Center worked with her to present her idea to our UI Sustainable Electronics Campus Consortium, to see if instructional technology groups on campus might be interested in exploring her concept to reduce battery waste, labor, and associated costs. Representatives of the CITES instructional technologies group were intrigued, and worked with Katie to create a prototype of a 3D printed adapter for the microphone packs they use, which would allow for the inductive charging of rechargeable batteries for the packs. Watch a video of her explaining the concept over here.

[embed]https://www.youtube.com/watch?v=xe6nvpYjYMY[/embed]

Katie graduated, and although she was unsuccessful in identifying students to continue her work, CITES was interested in perhaps pursuing a pilot of the technology on their own. The reprint created at the Illinois MakerLab was to correct a slight flaw in the design, which was keeping the rechargeable battery from seating properly in the microphone pack.

As students, we should be inspired by Katie and work towards thinking out of the box. We do not have the design and manufacturing limitations that earlier generations may have encountered. By expanding our imagination we can achieve innovations that could revolutionize industries. At the MakerLab we are working constantly we students and faculty members to do just this. Don’t pass on this opportunity, contact us at uimakerlab@illinois.edu or come visit us at 515 E. Gregory Drive, BIF #3030, Champaign, Illinois 61820.

Read more stories about Makers like Katie. Like us on Facebook, follow us on Twitter and on Google Plus to be the first to hear about other workshops, meetups and deals at the MakerLab.

Meet the Maker: Boyu Ji

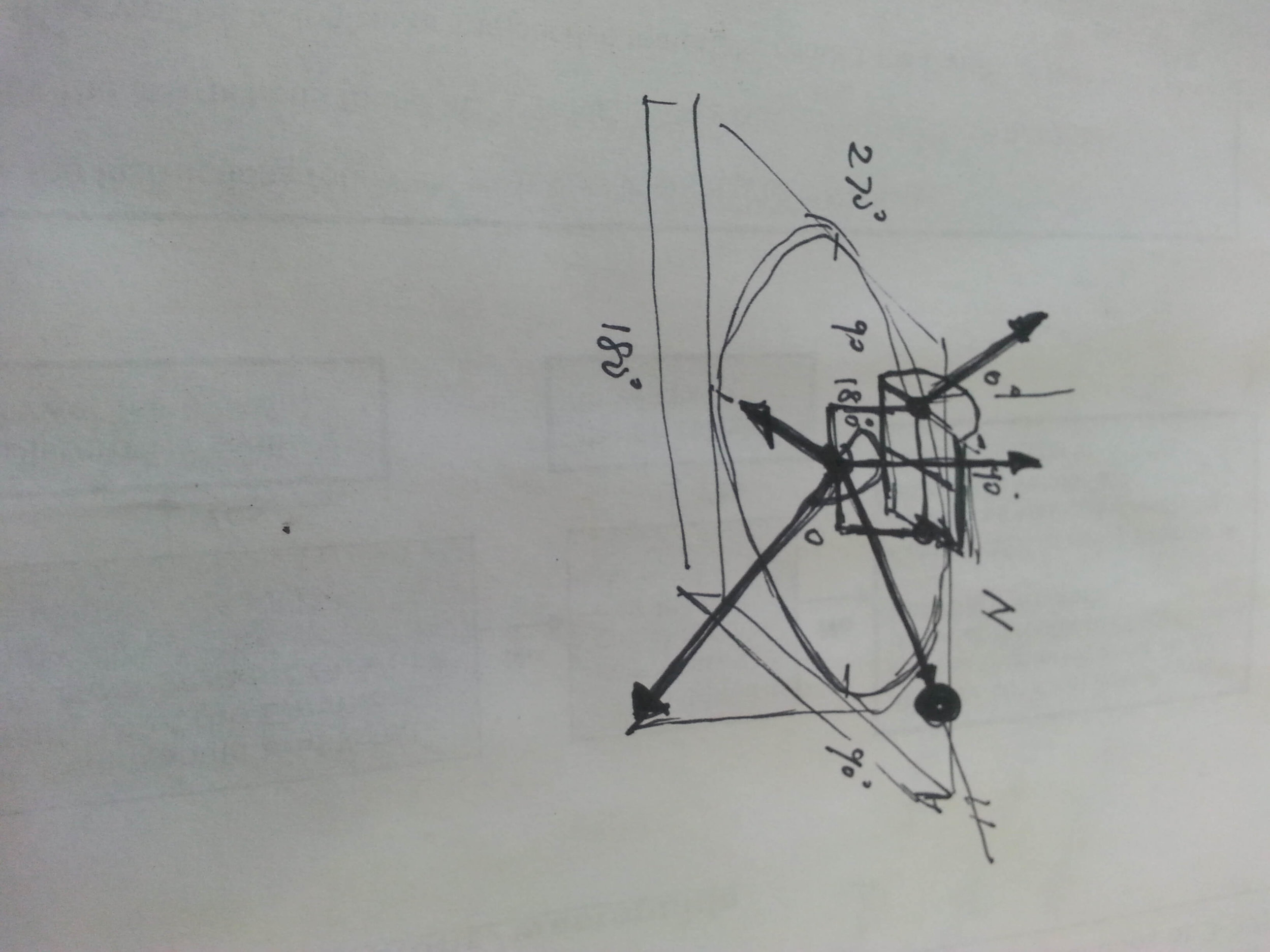

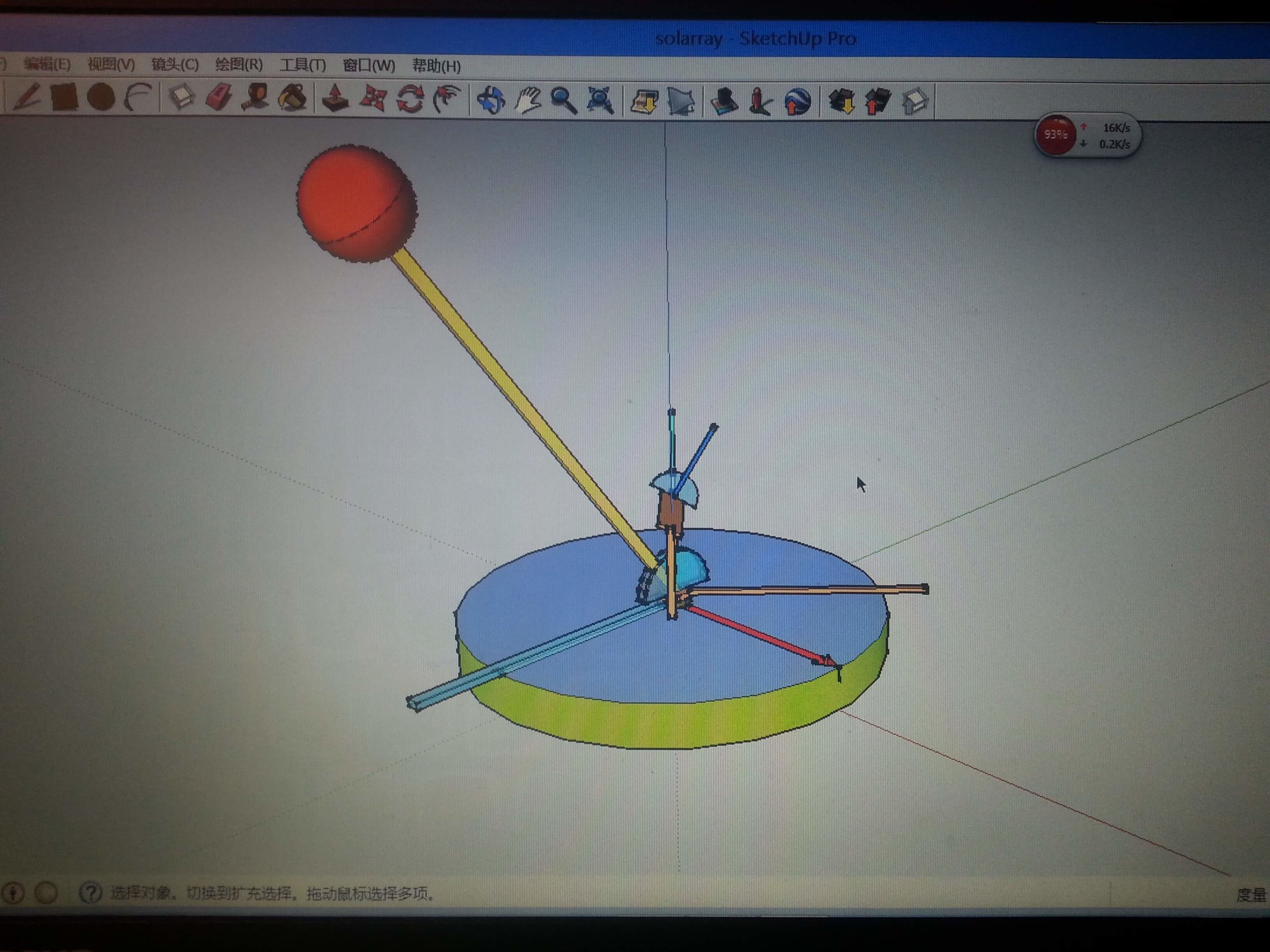

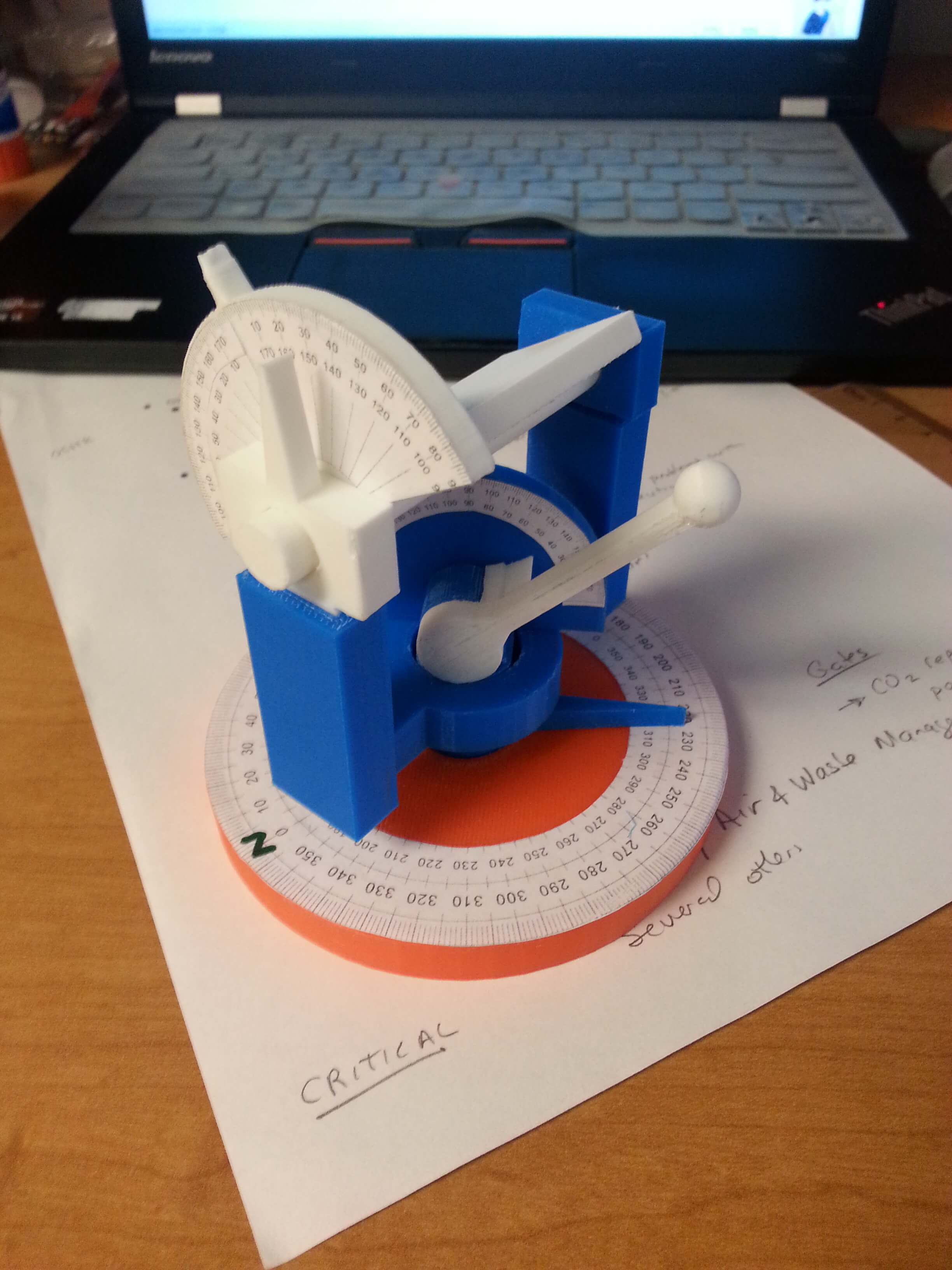

/3D printing allows us to create, limited only by our own imagination and creativity. Boyu Ji is a prime example of this. He took advantage of an opportunity during his Agricultural and Biology Engineering course, ABE 498 on Environmental Control of Buildings and decided to print a Solar Angle Module. ABE 498, currently taught by Professor Angela Green is a course about the built environment and its relationship with humans, animals and plants. You must be thinking how can 3D printing help here? Boyu Ji found that answer and came to us with a vision in mind to create a Solar Angle Module.

A Solar Angle Module is used to calculate the heat generated from sunlight on a surface. He explains:

“The bottom protractor scale of this module is used to show the azimuth direction of sun and the face direction of a building; the middle scale is used to show the altitude angle of the sun and the top scale is used to show the tilt angle of the roof or surface of wall. So with some equation [we learned] in ABE 598, those angles can be used to calculate the heat from sunshine on the building surface. In the future, with some Arduino motor control and light sensors, it can be improved to find the position of sun, turn the compass automatically, and calculate the heat transform by an equation in the program.”

He was able to print this beautiful design and used it for his class. The Illinois MakerLab has been setup just to make such ideas come to reality. Whether it’s for a student project or personal use, come visit us. Our Gurus will be more than happy to help bring your vision to reality.

Illinois Ranked in Top 5 3D Printing Universities

/An article recently posted in Inside 3D Printing recognizes the Illinois MakerLab as one of the Top 5 3D Printing facilities in a US University. This article notes that the MakerLab is "the world's fist Business School 3D Printing Lab." The other universities in this list include Alabama, Cornell, Indiana, and Michigan.

Join the Making Revolution at the MakerLab. Read about our Makers, and see the impact we make across campus.

Sign up for Workshops, or the for-credit courses for Spring, or just drop by during open hours. Stay tuned for updates by subscribing to our newsletter, Liking us on Facebook, or just follow us on Twitter.