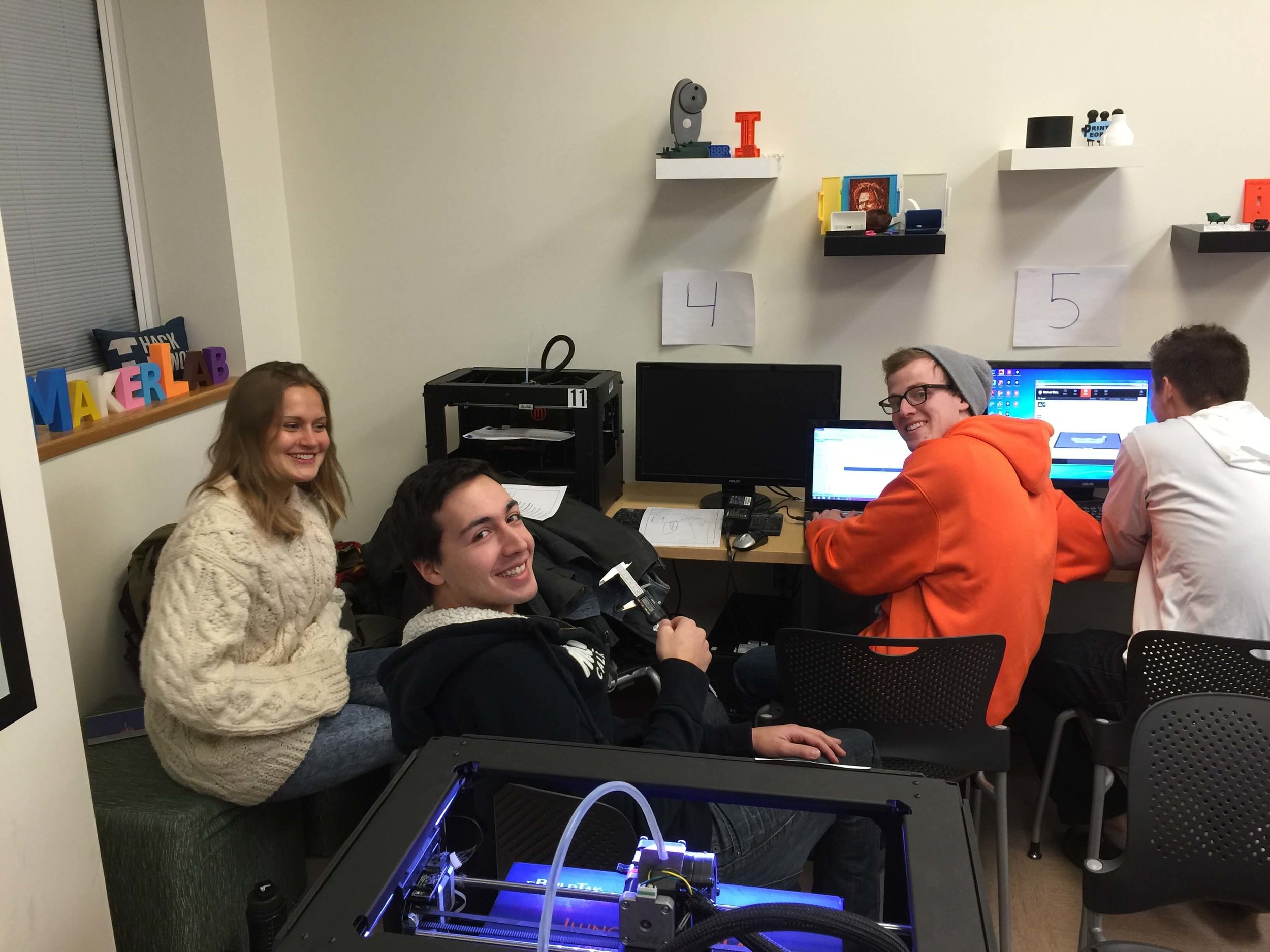

Become a Certified Maker

/We are excited to launch a set of workshops on 3d printing, modeling and scanning. Take all four and become a certified maker, along with a Digital Badge that you can show on your profile on social media or LinkedIn!! 1. 3D printing 2. Basic 3D Design 3. Advanced 3D Design 4. 3D Scanning

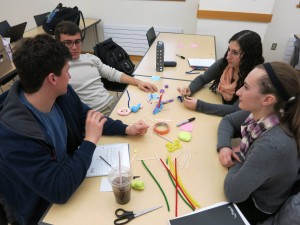

These workshops have been designed to help you understand the fundamentals and get you hands-on practice in each session. The workshops start with the basics of 3D printing and go on to more advanced methods of 3D modeling and end with a workshop on 3D scanning. All courses must be completed in order to be certified by the MakerLab. We guarantee you an evening of fun and learning. Hurry! Each workshop is limited to 10 students!

Find out more and sign up for the Workshops now.

Stay tuned for updates on new workshops by subscribing to our blog feed, or just get our posts via email. You can also like us on Facebook or follow us on twitter to stay updated. You can contact us at UIMakerLab@illinois.edu