3D Printing: An Interdisciplinary Perspective

/Guest Post by : Joe Bradley, Adjunct Professor of Business Administration, who is interested in challenges at the interface of product development, technology management, intellectual property management, and corporate entrepreneurship. It seems that everywhere you turn 3D printing technology is in the news and popular press. 3D printing technology is making its way into the hands of the masses, with an excitement of what the future may hold. Many people wonder if this technology is just hype or a passing trend and doubt how it will “really” change the status quo. Past evidence from many seemingly disruptive innovations suggests that 3D printing technology’s current and potential impact on society should not be taken lightly. The growth and expansion in 3D printing is another enabler to democratizing innovation, as suggested by Professor Eric Von Hippel. User-centric and personalized innovation will be the way of the future.

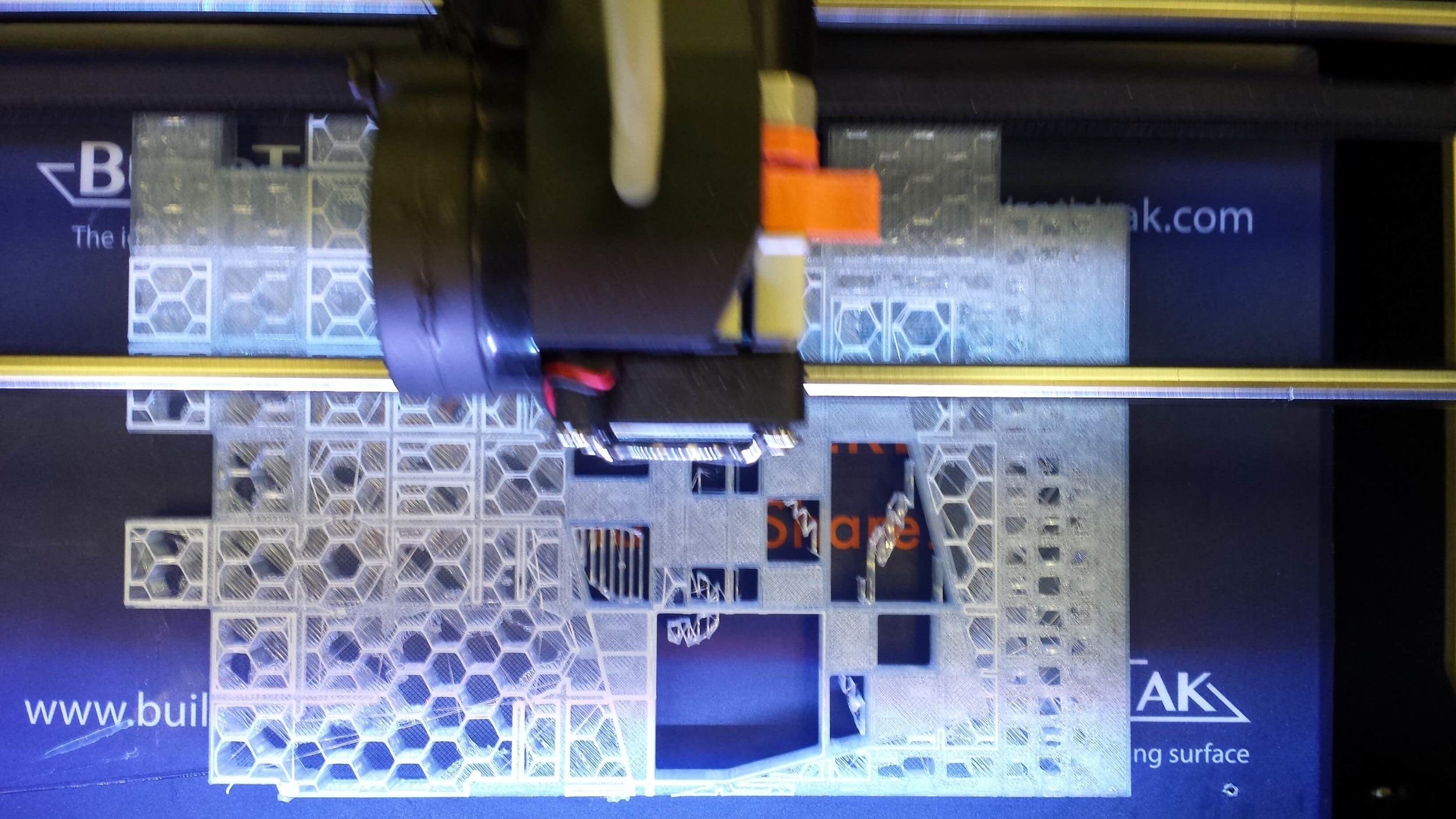

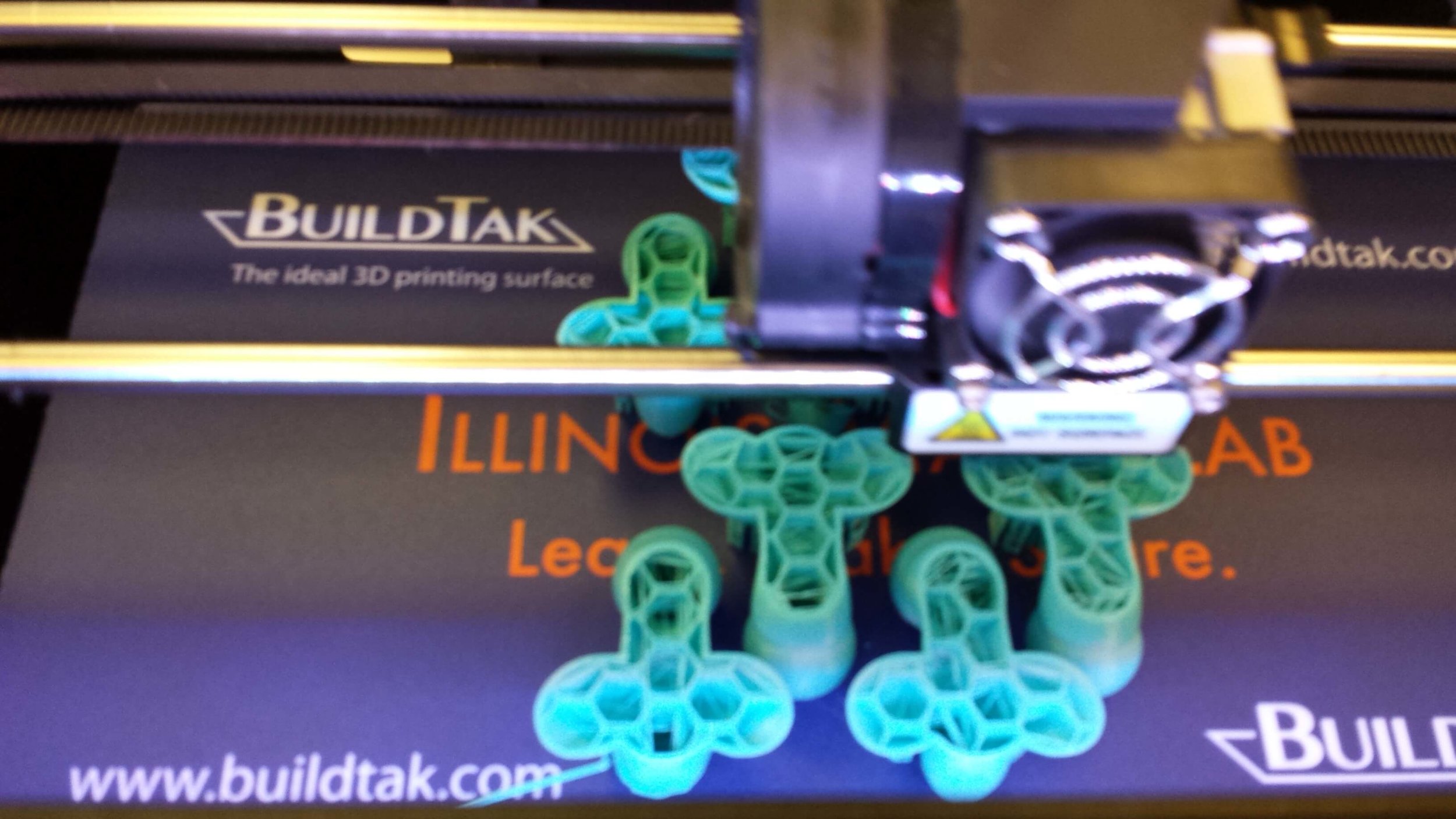

3D printing has been around since the 1980’s. It was more widely known and used in engineering, manufacturing, and design disciplines as “additive manufacturing.” When 3D printing technology turned attention to the commercial market, printer suppliers developed products for multiple market segments. These printing devices are now found in high schools, universities, colleges, and on the desktops in the homes of many inventors, hobbyists, and entrepreneurs.

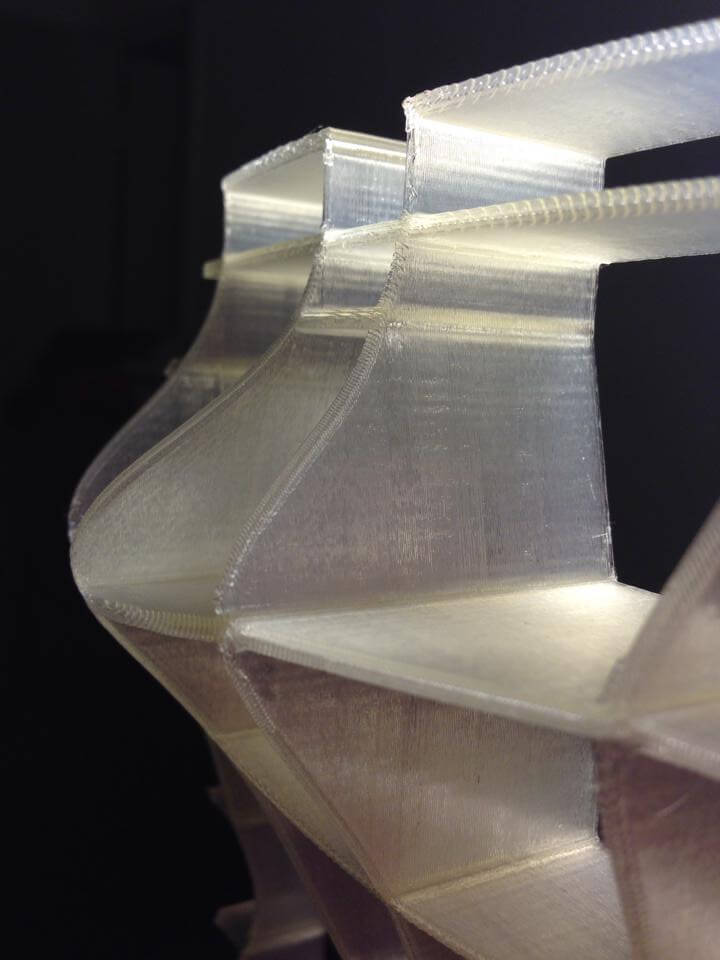

With the proliferation of 3D printed products by individuals of various skills and capabilities comes the issues of product quality, product liability, intellectual property protection, and many other technical, legal, and business issues. As this technology continues to improve and becomes available to and is embraced by more users, the demand for 3D printed products will increase and these issues will only become amplified.

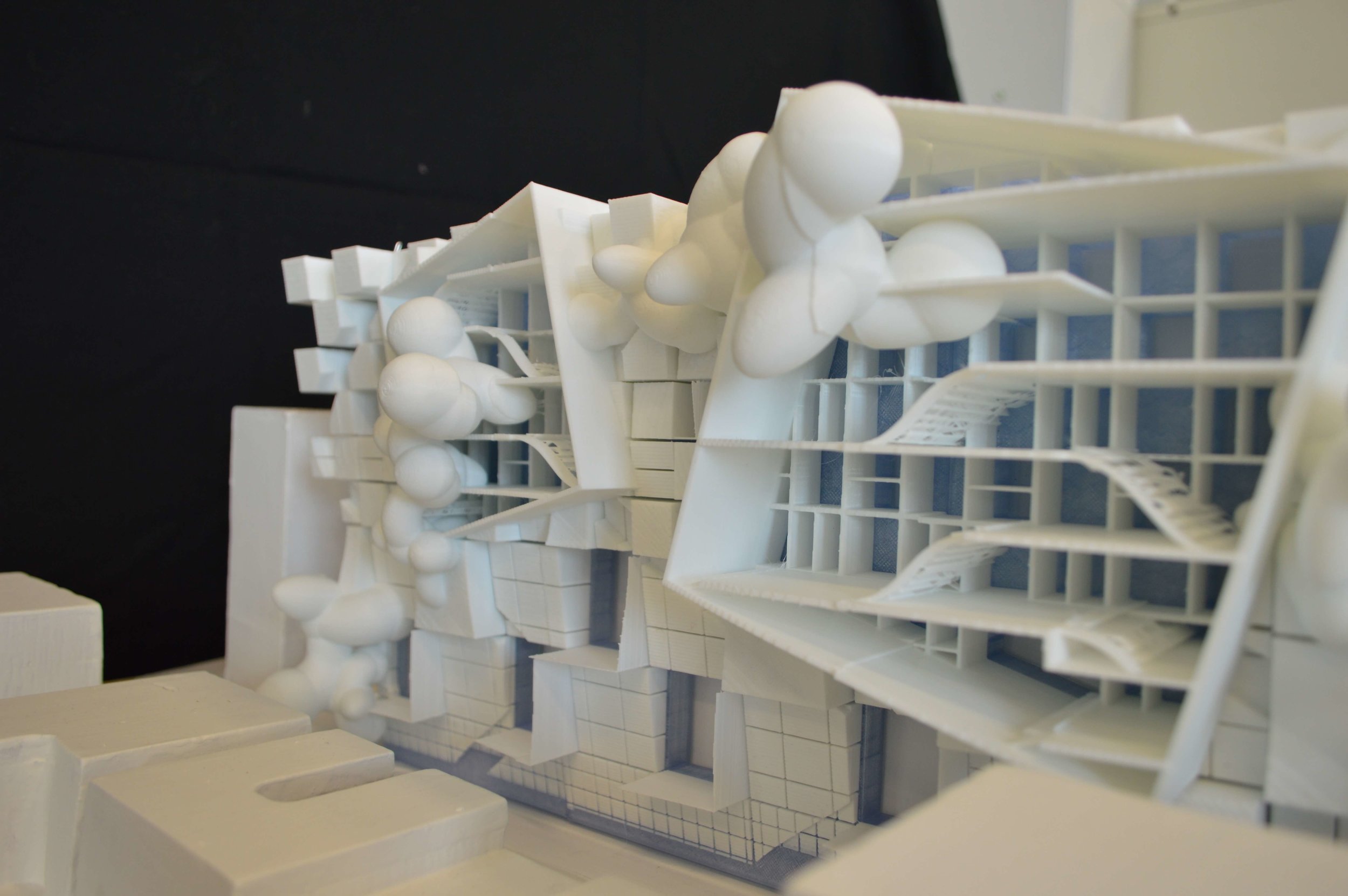

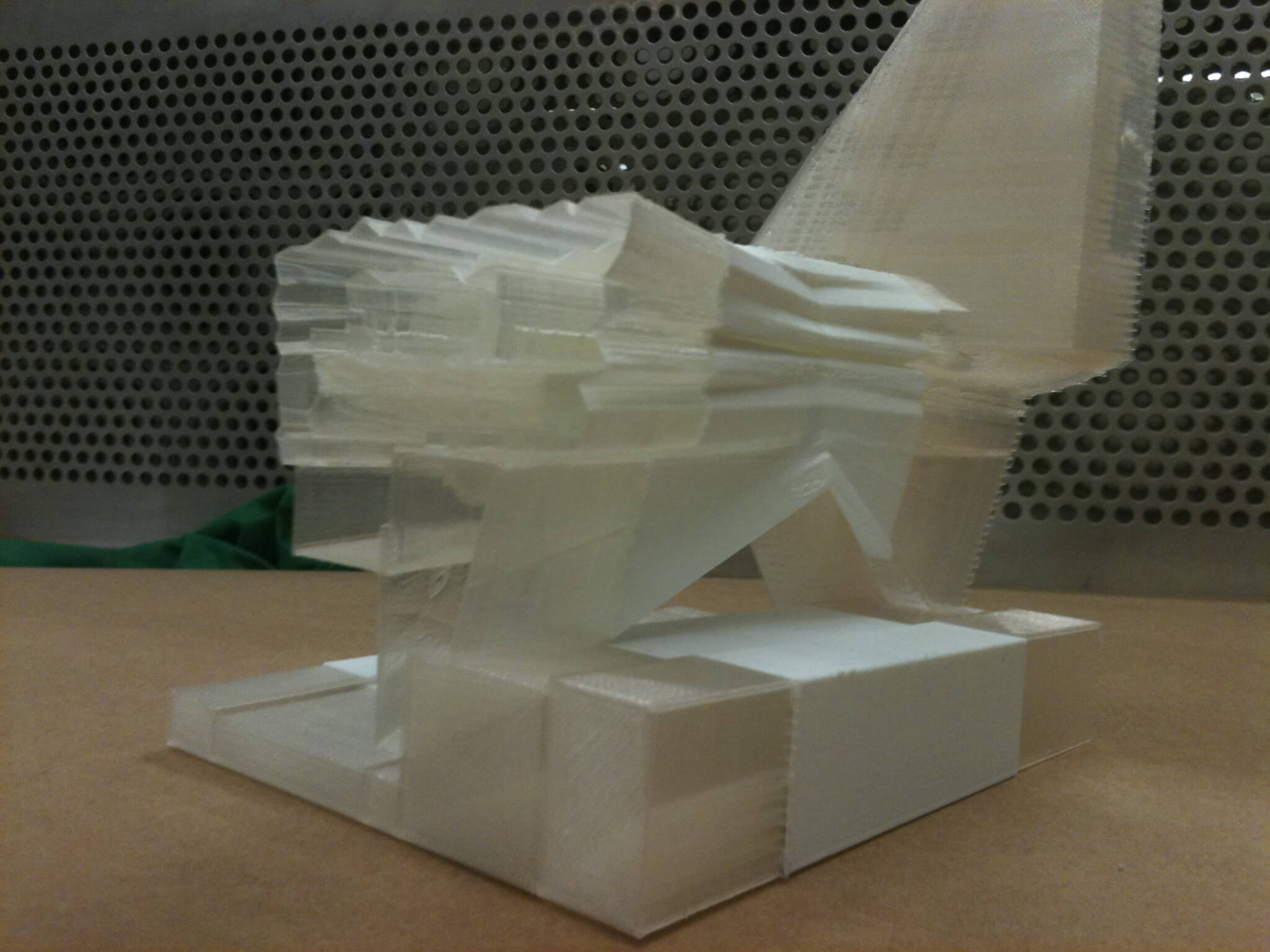

We must approach the discussion on 3D printing from an interdisciplinary perspective because questions concerning the future evolution of 3D printing spans over multiple disciplines. The MakerLab at the University of Illinois College of Business provides the perfect platform to facilitate a discussion on the challenges and possibilities of this disruptive innovation. There needs to be a discussion on how to develop the technology and what elements of the technology should be standardized. A discussion on how an organization can proactively manage their intellectual property while also providing a platform for their customers to modify and personalize the products. A discussion on corporate policy and how it needs to be developed in a way that does not penalize lay users of 3D printing technology, but support their innovative effort. The MakerLab is an interdisciplinary destination, for students and faculty from business, art & design, engineering, architecture and many other disciplines, to collaborate and become familiar with 3D printing technologies.

In this series on Intellectual Property issues , we hope to explore some of the challenges and to better understand how 3D printing can continue to have a positive impact on society and be exploited to its potential.