Meet the Maker- Fritz

/"The thing about being a designer is that the attitude and curiosity don’t retire."

- Charles Danielson (AKA Fritz)

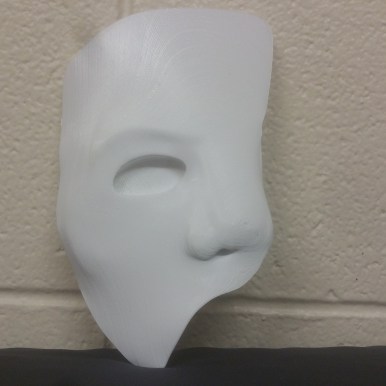

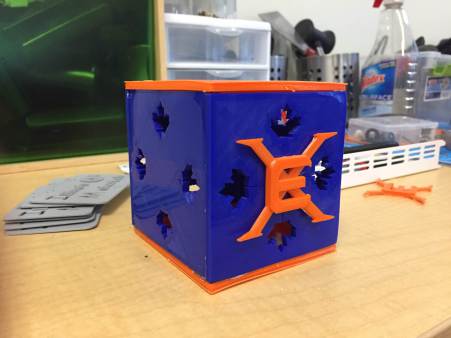

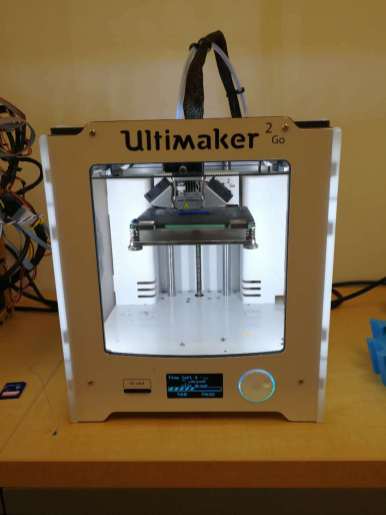

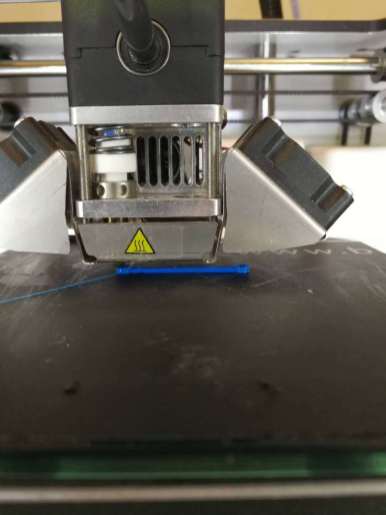

Fritz may be retired from his job as an Art and Design Educator but his imagination and passion for 3D printing never stops. Fritz is a University of Illinois Alum after attending school here for both his bachelor's degree in Industrial Design and master's in Graphic Design. Fritz first found our lab through our series of workshops. There he learned the possibilities of what 3D printing can do! Afterwards, he let his imagination run wild and started using SketchUp to design his own models. Recently he designed a phone holder for his car that would rest on the dash board beyond the steering wheel so that he can drive hands free but still be able to see his screen. This is extremely useful when using Google Maps! This is only one of Fritz's many designs that he has made over the years and we hope to see him in the lab soon to print another!

Stay tuned for MakerLab updates by subscribing to our newsletter, liking us on Facebook, or following us on Snapchat(uimakerlab), Twitter or Instagram. Want to be featured in a blog post? If you have an interesting story that you would like to tell about making at the lab, share it with us by emailing UIMakerLab@Illinois.edu!