Illinois MakerLab makes prosthetic hands for a Civil War Tech Workshop

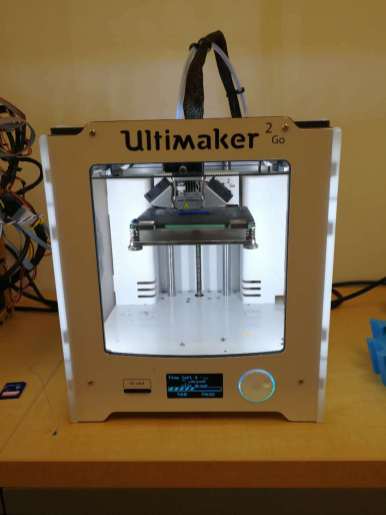

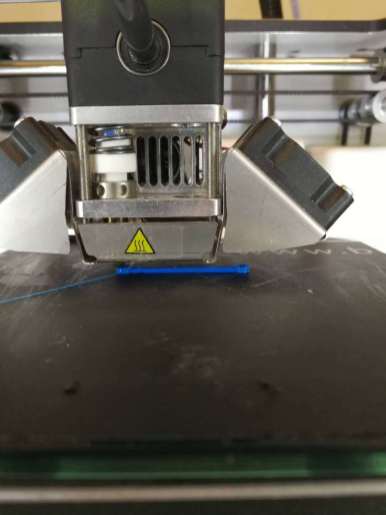

/The Illinois MakerLab was excited to collaborate with the Abraham Lincoln Presidential Library & Museum on a Civil War Tech Workshop. This event happened on January 6, 2018. This workshop was specific to medical advances in the Civil War era. Children and their parents learned about how medical research changed after the creation of the Army Medical Museum in 1862. The participants had the opportunity to assemble 3D-printed prosthetic hands printed by the Illinois MakerLab. Children learned about the evolution of prosthetic and technology during the Civil War. The workshop compared this historical information to modern-day 3D printing. The Illinois Maker Lab was thrilled by this opportunity. Our gurus and volunteers enhanced their 3D printing skills and learned more about how 3D printing relates to the medical industry. Featured is a video time lapse of the 3D prostheses in action! There is a link to read more about this story on News Channel 20. We would like to thank the Education Coordinator, Betsy O’Brien, for reaching out and making this partnership possible.

Stop by the Illinois MakerLab to learn more about projects like these or create one of your own!