Exploring the Fab Lab- Digital Making 2017

/Guest Post: ChaseThis collection of posts refers to the Digital Making Class offered here at Illinois. Each week students are required to write down what they have learned through the week. Below is a summary for week 6 written by Chase.

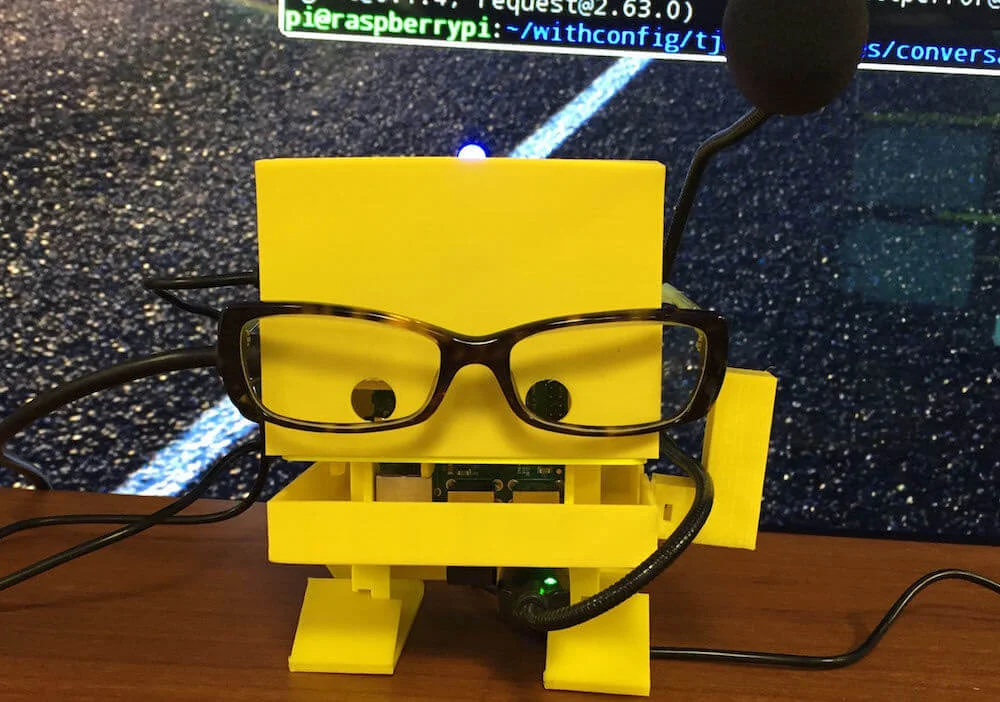

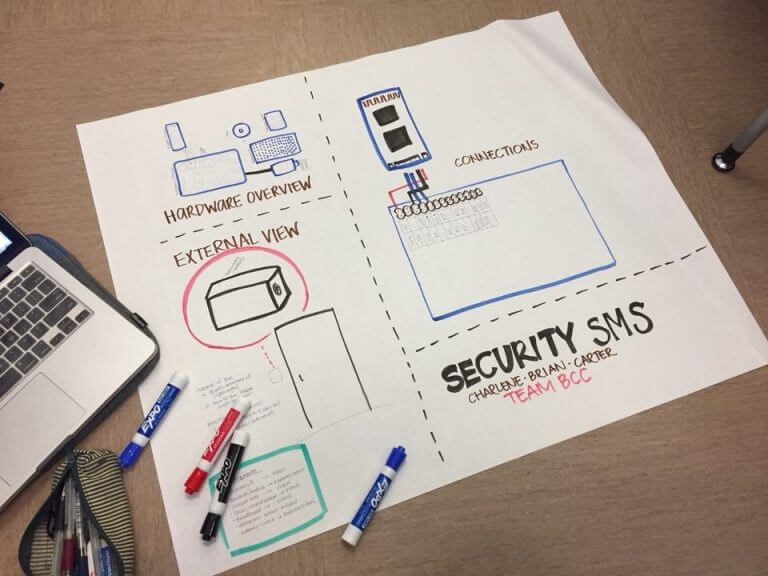

This week we engaged in the second phase of a continuous three-part series meant to offer exposure to the myriad of activities offered at the Champaign-Urbana Community Fab Lab. The Fab Lab is a leading-edge open and collaborative work-space for design, creation, and printing through the use of computer-driven technologies, such as 3D printing, lasering, inkscape, and soldering. Since the making space offers such a vast array of opportunities to its various users, the class was divided into three separate groups during our first session, with each group rotating between the three main functions of the lab: laser cutting, soldering, and coding.

The first station was laser cutting. The objective of this part was to assemble the wood cube that would house the photo dependent LED light resistor. The software used to create the designs on the sides of the cubes was Inkscape, a completely free, open-source platform that appears to be user-friendly yet still able to make complex designs. The laser uses subractive manufacturing to etch the designs into the wood which created the images, while also making the actual cuts to create the box.

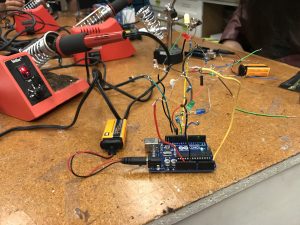

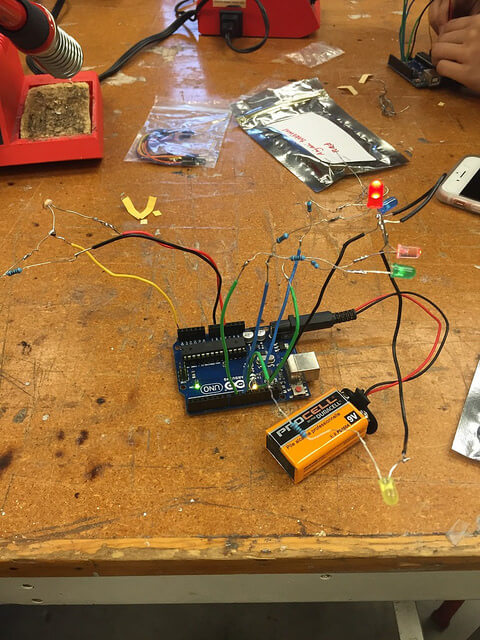

The second station was soldering. Soldering allows for more accurate and uncluttered connections between various electronic parts, such as wires, resistors, and other components. An additional benefit of soldering is the ability to maintain the original shape of the soldered metals, considering that the solder has a much lower melting point than the adjoining metal. Since the fusing occurs at much lower temperatures, the metals that are being connected do not warp in shape or size, nor do they melt. Lastly, soldering allows for the joining of multiple wires using a single focal point. This can allow electricity to be conducted, as all the wires have been bonded together.

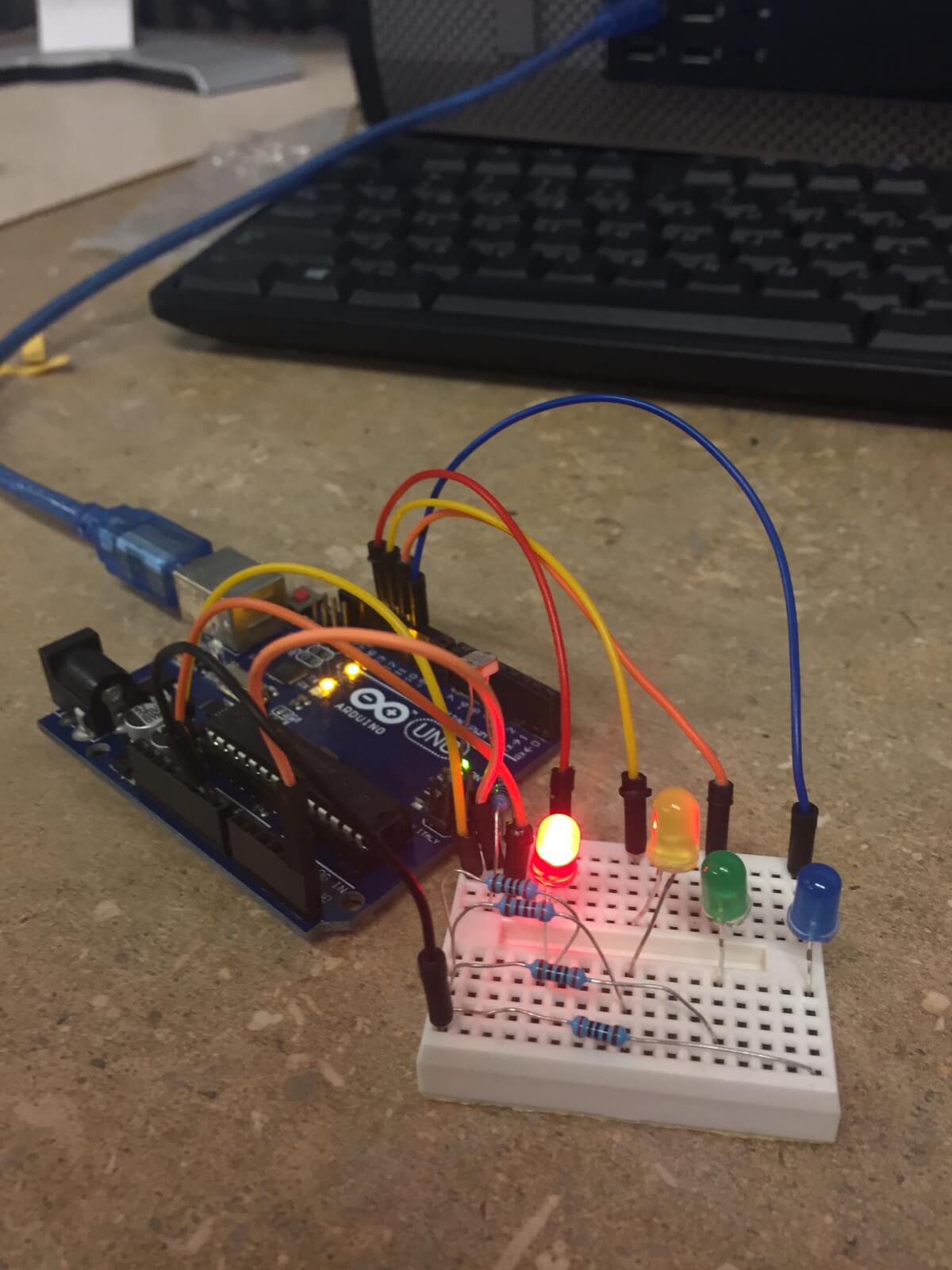

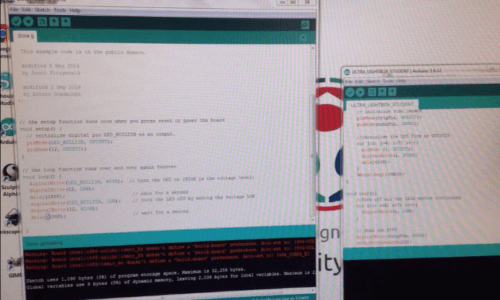

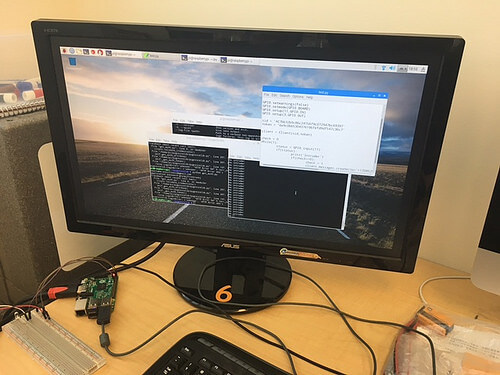

The third portion involved using Arduino’s open sourced software. Arduino’s simple platform allows for makers with only basic coding experience to still utilize the immense functionality of the technology. The object that was being encoded today was a photo resistor (light dependent resistor) with LEDs. By connecting the LED lights to the light resistor and being guided through some of the basics of the Arduino code, the LED lights extinguished in the presence of light and flashed during times where there was no light (when it was covered by a hand, for example).

Are you an undergraduate at Illinois and need a class for Spring 2018? Take Digital Making! Apply now by emailing your resume to vishal@illinois.edu, with a short note explaining your interest in the course and any skills/passions in making that you bring to the course. Application will be open until November 15th. And don’t forget to stay tuned to MakerLab updates by liking us on Facebook, or following us on Twitter or Instagram.