Guru Spotlight: Jim

/The MakerLab Gurus are an integral part of the lab, helping with day to day functions, completing orders, and running workshops. We've decided to showcase some of the personal projects that our Guru's are able to work on in their spare time. In this post, we will be looking at designs printed by our Guru, Jim.

The Type-33 Guided Munitions Launcher, also known as the Needler, is an iconic weapon from the Halo video game series. It’s also an impressive 3D print. 11 Pieces, 14 needles, and 16 connecting pins. It is a scale model, around two feet tall by two feet long. The pieces were primarily held together with connecting pins and super glued to hold. The needles friction fit into the top. This is a great example of what spray paint can do for some cool 3D prints. This model was a thingiverse file by Ethan Newhouse. Printing time was around 40 hours. Another 10 hours for painting and drying and he needed only a few minutes to glue it all together.

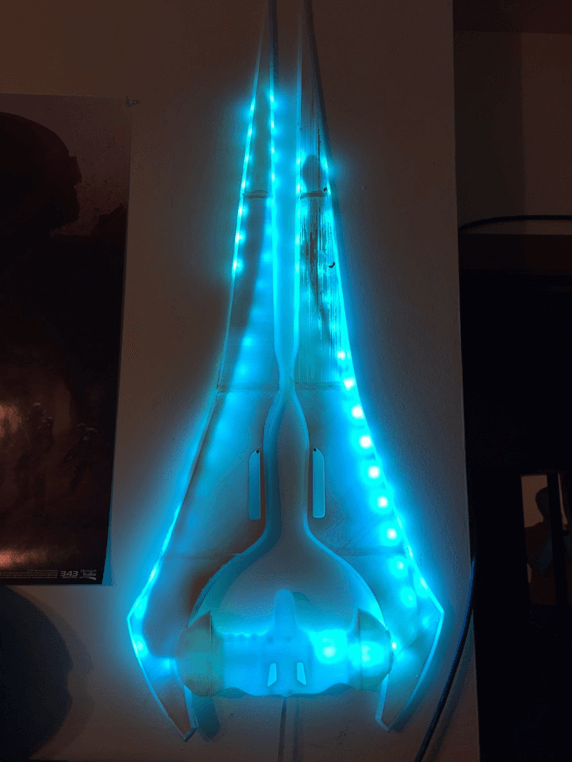

The Type-1 Energy Weapon is a fearsome melee weapon wielded by the Elites in the Halo video games series. While generating plasma in the shape of a blade is just a little beyond our technology, it of 19 interlocking pieces and an 8 foot LED strip to make a great wall decoration. Get creative with your 3D prints at the UIUC Makerlab. The pieces all were glued together at their edges. I found this on thingiverse, by adafruit. Printing took around 15 hours, assembling took another 2 or 3, as the flat, thin faces were difficult to glue together.

Falchion is an Iconic hand and a half sword from the Fire Emblem universe. While it hasn’t received any post 3D-printing work beyond putting it together, it showcases a unique type of clear filament and helps to think outside the size of a build plate due to its eight pieces. It’s also a far less dangerous way to hang an interesting sword on your wall. Originally a thingiverse file by OnyxIbex. Printing only took 10-12 hours. Assembling was rather quick. Flat faces of the blade pieces were superglued together.

First of all, for any fans of the Star Wars Universe, I have created a 5-piece replica (with my own iteration on coloring) of Obi-Wan-Kenobi’s lightsaber. Each piece took approximately 2-3 hours, which fluctuated with the level of detail. This is seen in the third and fourth Star Wars movies and was designed by thingiverse member falken76.

First of all, for any fans of the Star Wars Universe, I have created a 5-piece replica (with my own iteration on coloring) of Obi-Wan-Kenobi’s lightsaber. Each piece took approximately 2-3 hours, which fluctuated with the level of detail. This is seen in the third and fourth Star Wars movies and was designed by thingiverse member falken76. If you or anyone you know has an interest in aviation or commercial flight, then this model of the Embrayer ERJ 145. This design took about 5-6 hours and took a little bit of work to remove supports. However, this design by navy876 turned out very well and is a fantastic example of a scaled model that can be used for prototyping and design ideas.

If you or anyone you know has an interest in aviation or commercial flight, then this model of the Embrayer ERJ 145. This design took about 5-6 hours and took a little bit of work to remove supports. However, this design by navy876 turned out very well and is a fantastic example of a scaled model that can be used for prototyping and design ideas. With the new movie Star Trek: Beyond coming out, I HAD to create a model of the series’ flagship. This model of the USS Enterprise is comprised of 13 different pieces that each snap together to create this awesome model. A design by RealAbsurdity on thingiverse, this model is sure to be a phenomenal creation for any Star Trek fans.

With the new movie Star Trek: Beyond coming out, I HAD to create a model of the series’ flagship. This model of the USS Enterprise is comprised of 13 different pieces that each snap together to create this awesome model. A design by RealAbsurdity on thingiverse, this model is sure to be a phenomenal creation for any Star Trek fans.