3D Printing in Sports- Digital Making 2017

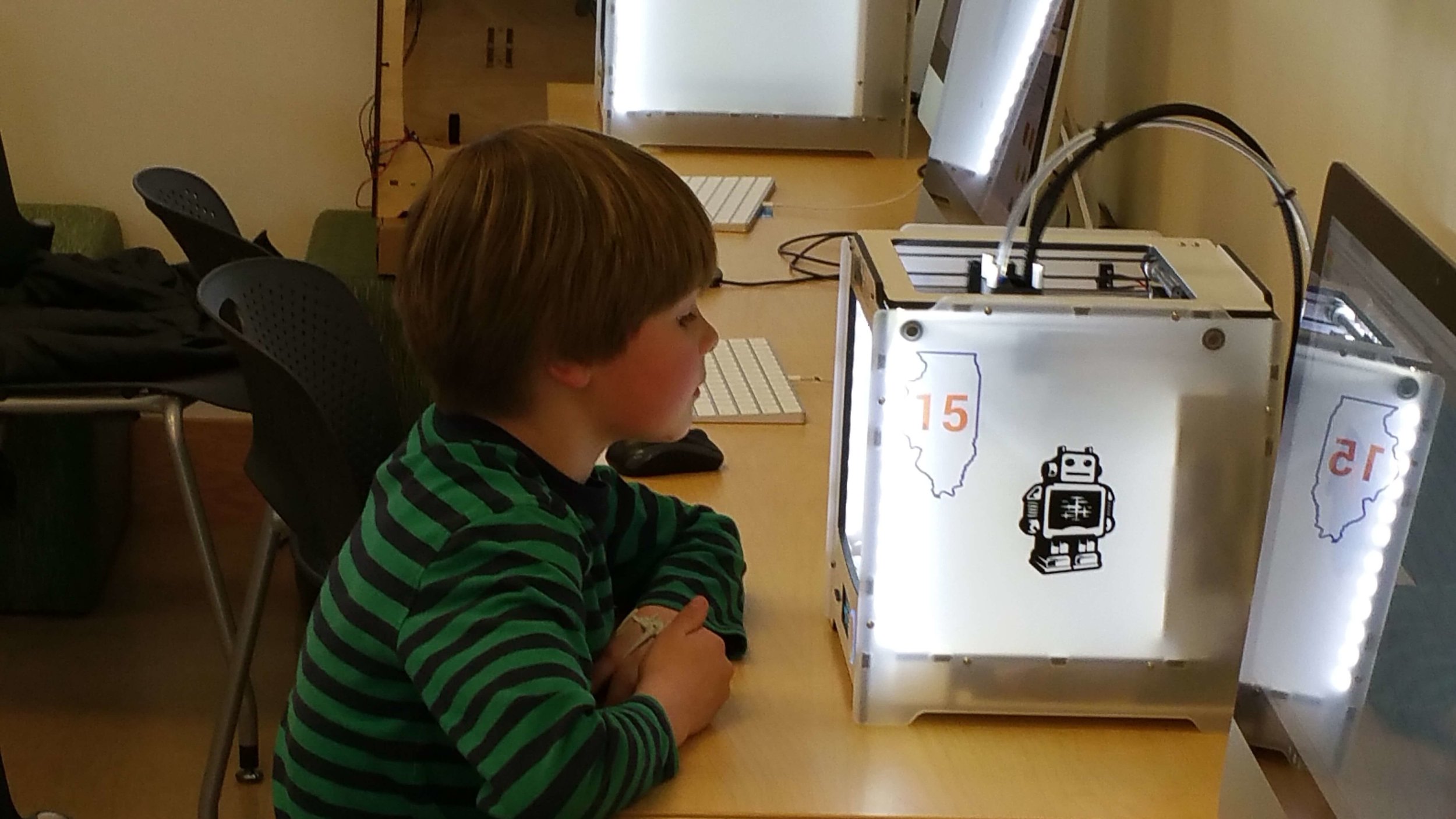

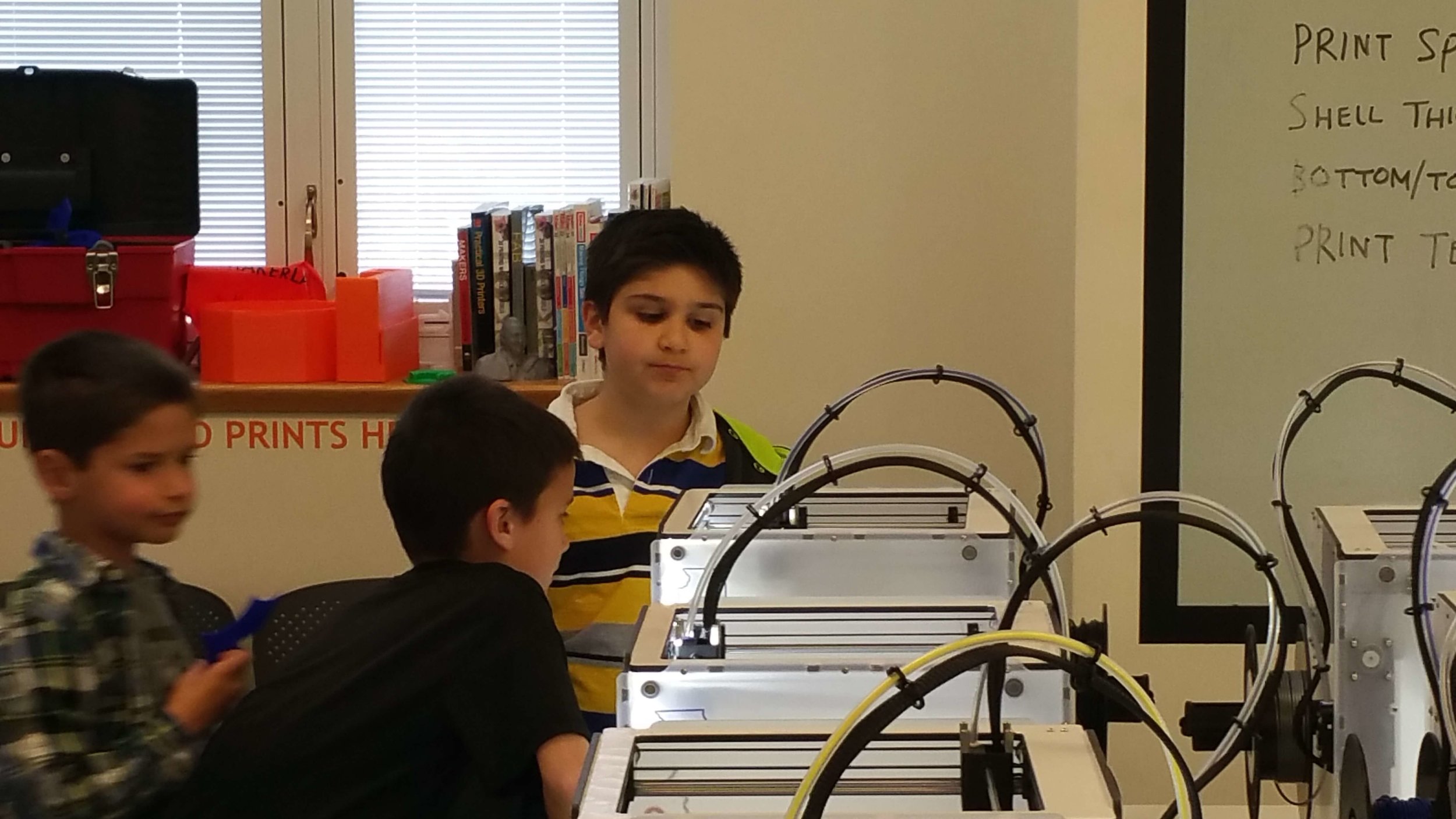

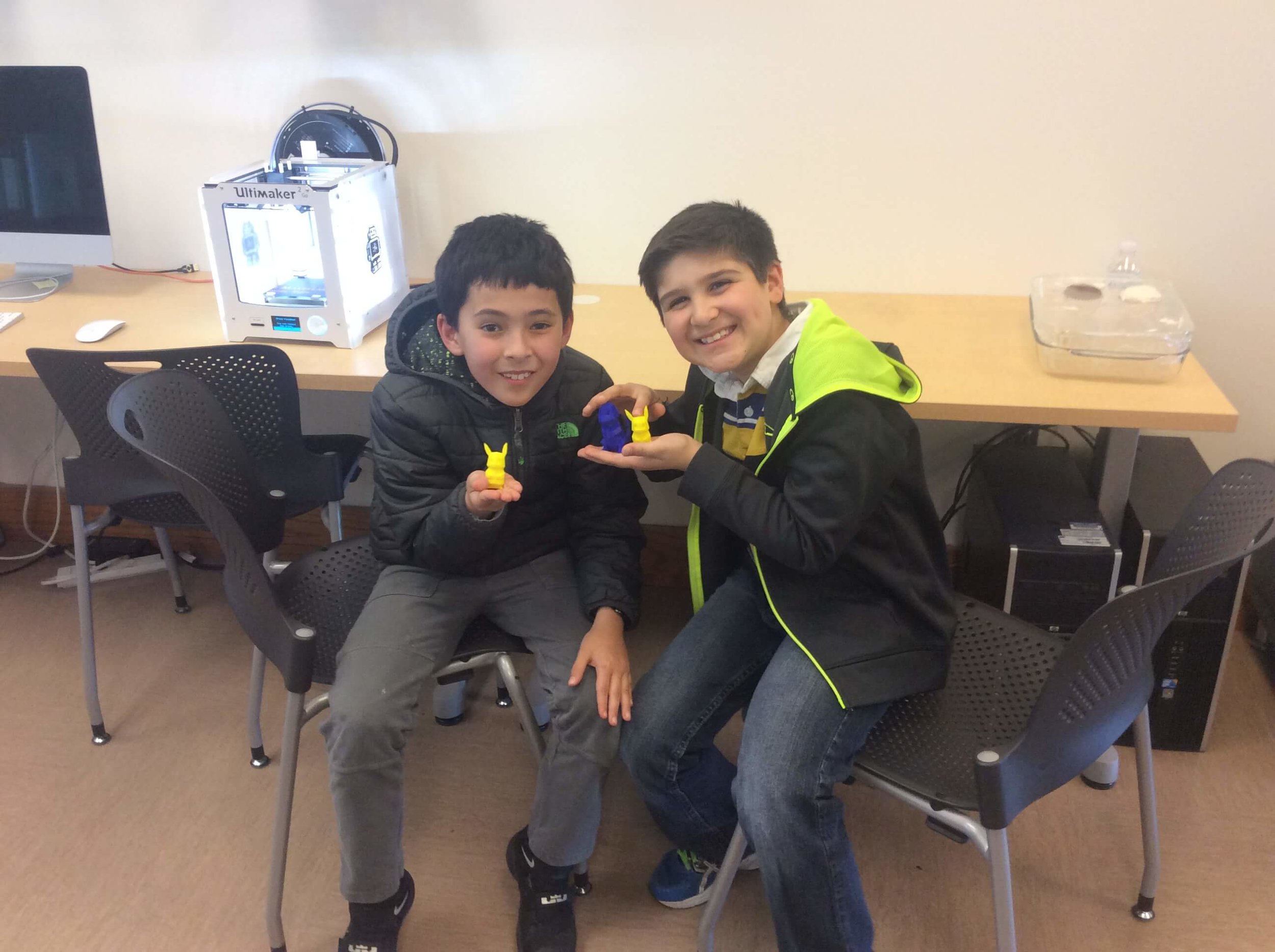

/Guest Post: Carter CarrollThis collection of posts refers to the Digital Making Class offered here at Illinois. Each week students are required to write down what they have learned throughout the week. Below is a guest post written by Carter Carroll about his findings on 3D printing in the sporting industry.

The capabilities of 3D printers will transform traditional manufacturing across all industries primarily because they lower costs, are more efficient, create fully customizable products, and are one machine that creates finished products as users digitally design. IP lawyer John Hornick states in his book 3D Printing Will Rock the World, that for these reasons, parts manufacturing companies will be the first to be overtaken by 3D printing with consumer products soon to follow (Hornick, 2015). For the sports industry, most of the manufacturing of consumer products falls under the category of sporting goods and equipment. These include major sporting brands such as Nike, Adidas, and Under Armour. It should be noted that the creation of sporting goods is by no means a small part of the overall sports industry, “The market for sporting goods in the United States has a projected value of almost $65 billion, and recreational transport and the equipment category accounts for 25 to 30 billion U.S. dollars in consumer purchases” (Jaaskelainen, 2016). The above reasons are just part of why sporting good manufacturers and users see value in use of 3D printing technology. Currently 3D printing can be regarded as a mutually beneficial innovation for sport equipment brands and consumers. Overall it is primarily the customization capability, and low cost accessibility of the products 3D printing technology can create, that provides the most value to industry stakeholders. Below are some products that companies and people alike have already created for the sport industry using 3D printing.

Certainly, the ability to fully customize products with 3D printing is the most prevalent way that the sport industry sector has been using the technology. For sporting goods manufacturing companies, the sporting equipment products they create are primarily for athlete use. The challenge with making sport athlete centered products is that every athlete is different. Additionally athlete consumers typically desire products that will improve performance, or to which brand they identify with. Providing athletes with custom equipment that will improve performance is in part what a big draw to what 3D printing manufacturing in sports is doing.

Are you an undergraduate at Illinois and need a class for Spring 2018? Take Digital Making! Apply now by emailing your resume to vishal@illinois.edu, with a short note explaining your interest in the course and any skills/passions in making that you bring to the course. Application will be open until November 15th. And don’t forget to stay tuned to MakerLab updates by liking us on Facebook, or following us on Twitter or Instagram.