Meet The Maker - Reese Richardson

/Our #makeroftheweek is Reese!

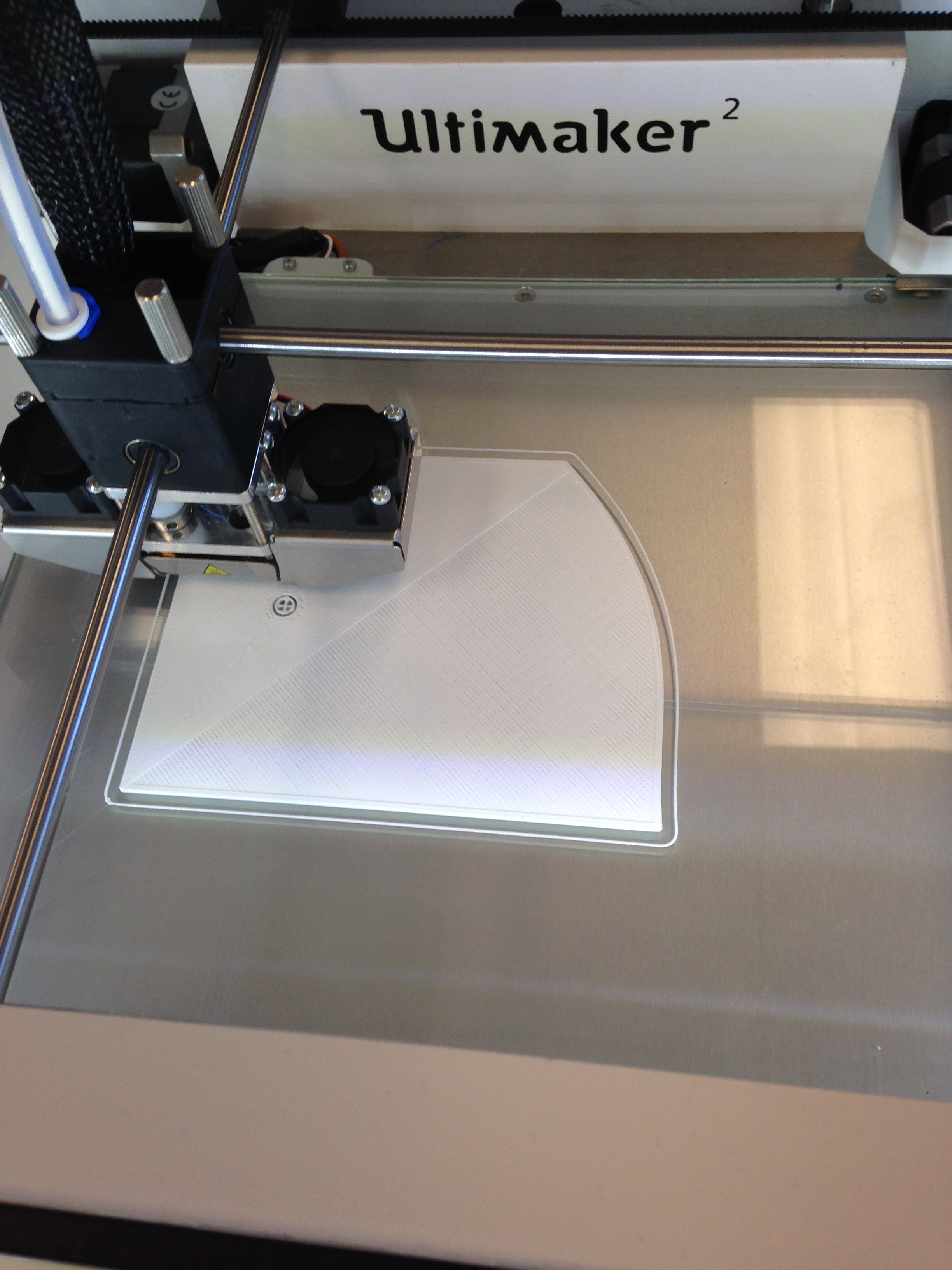

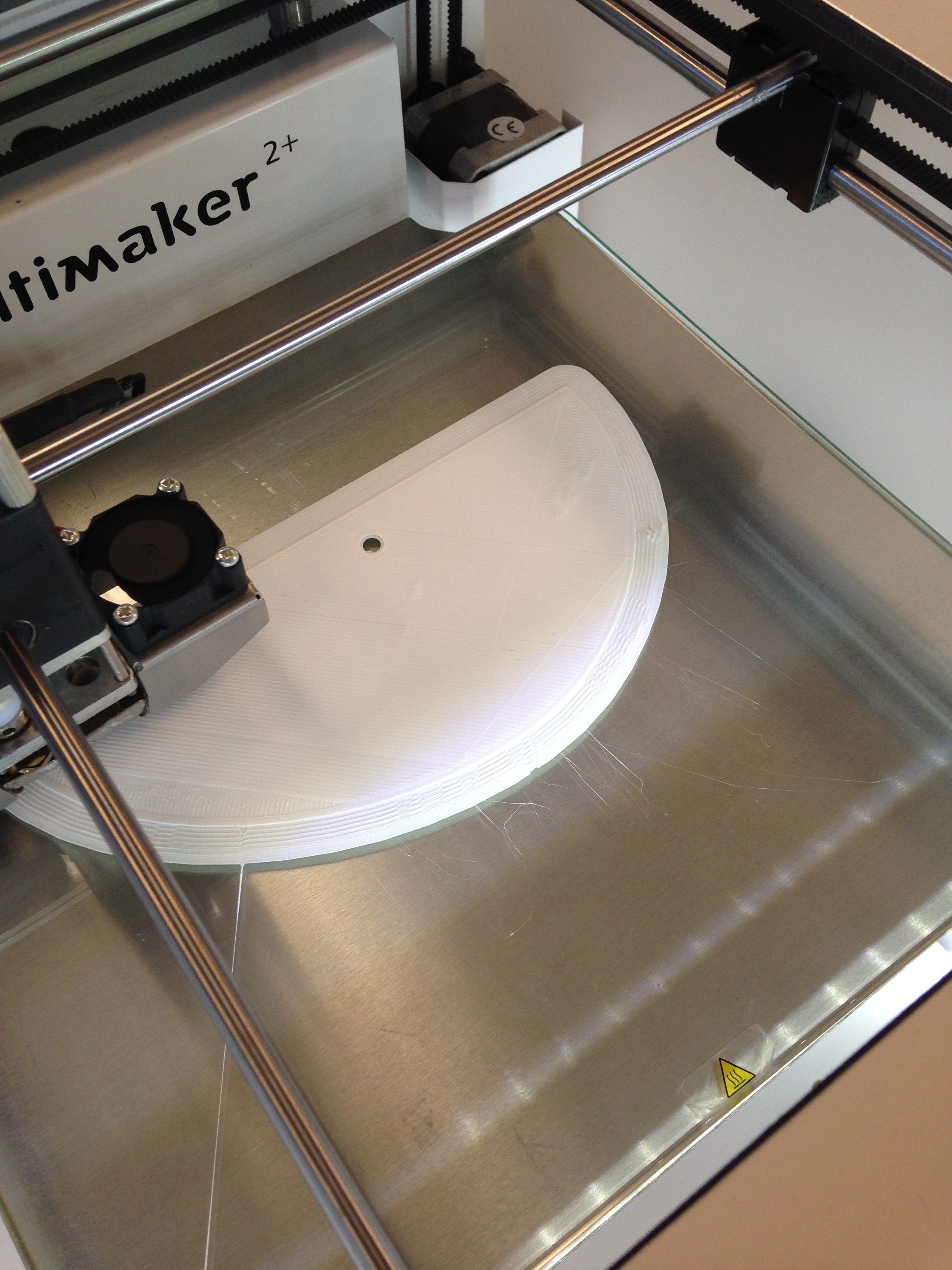

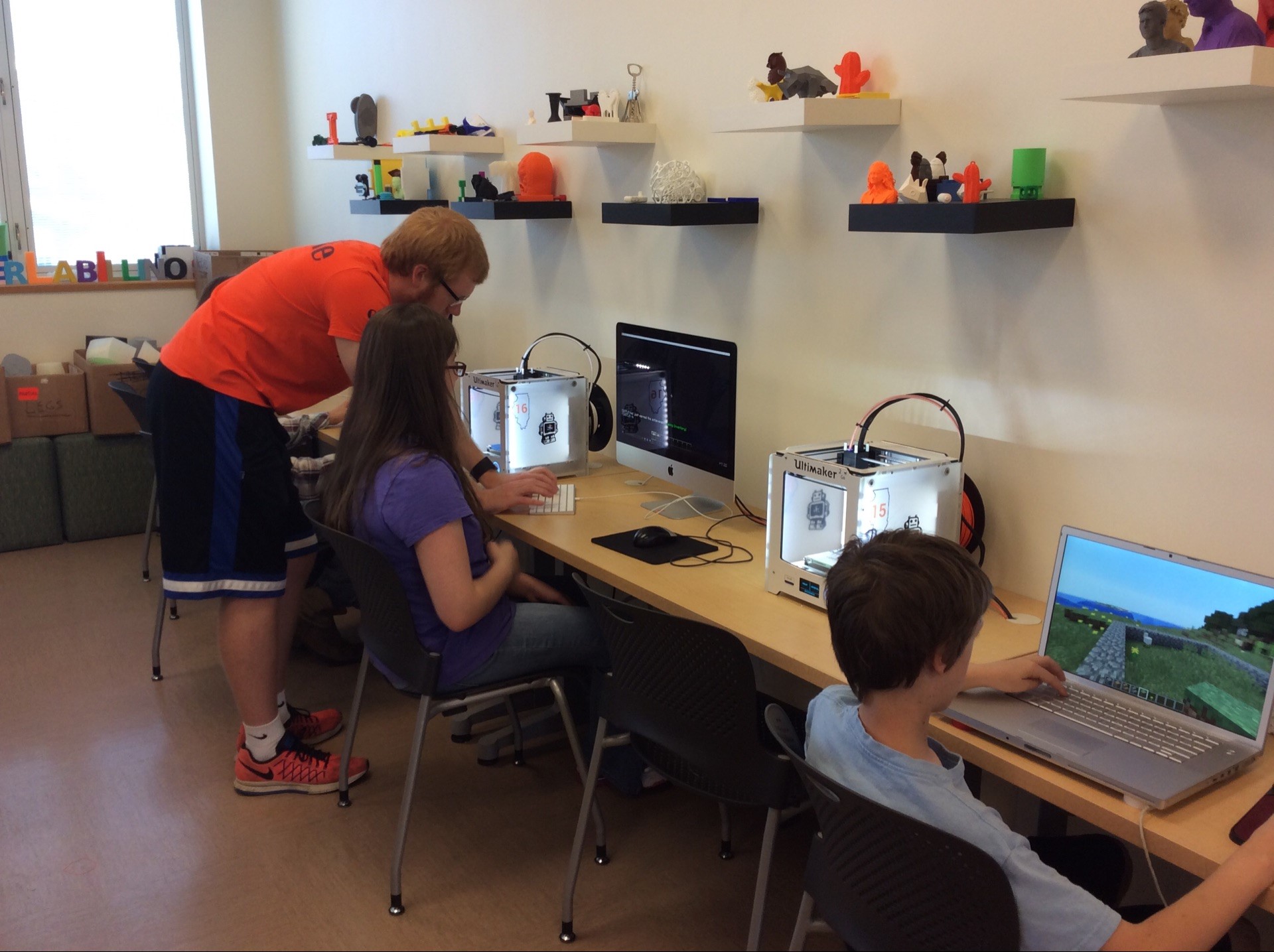

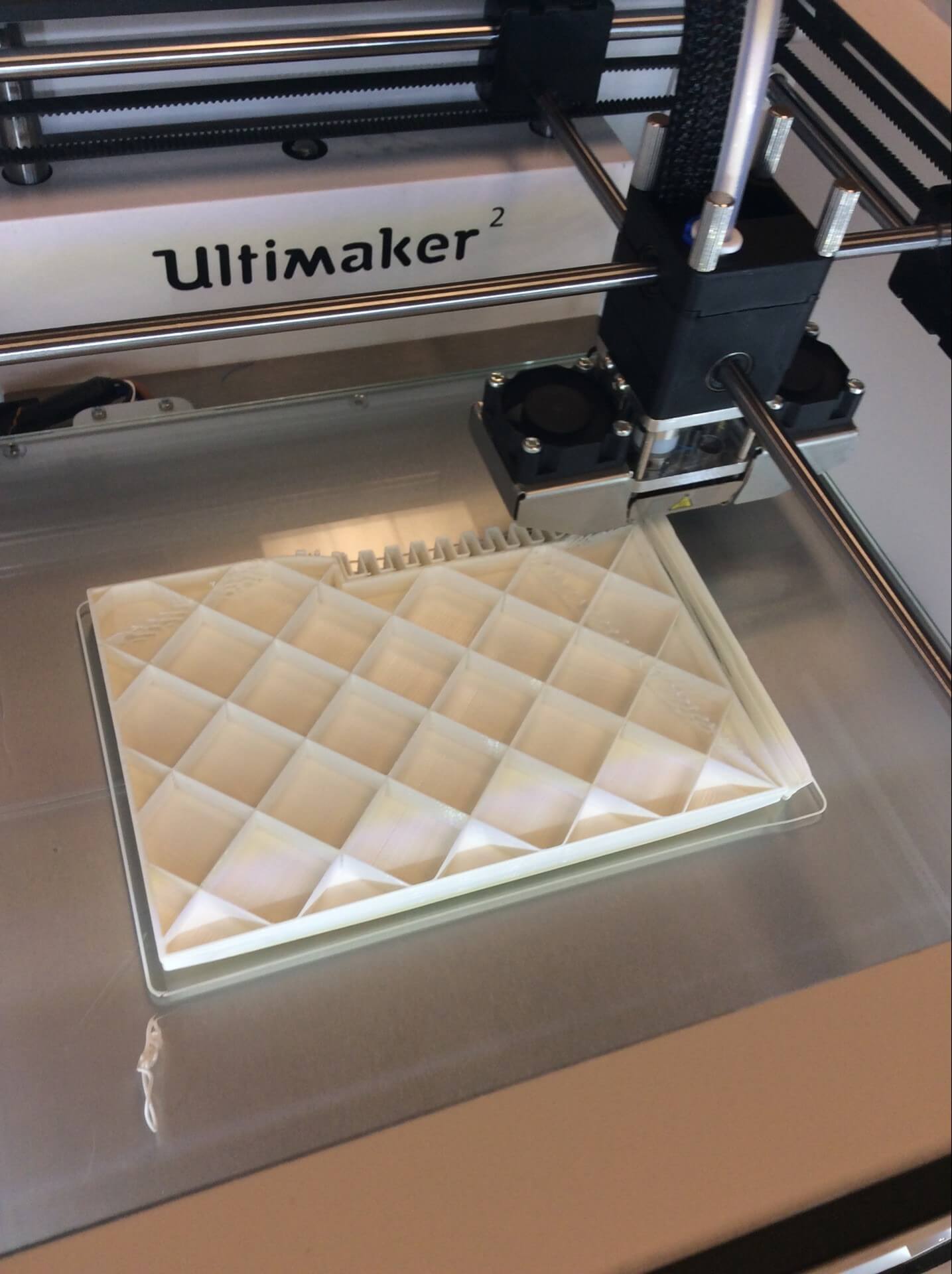

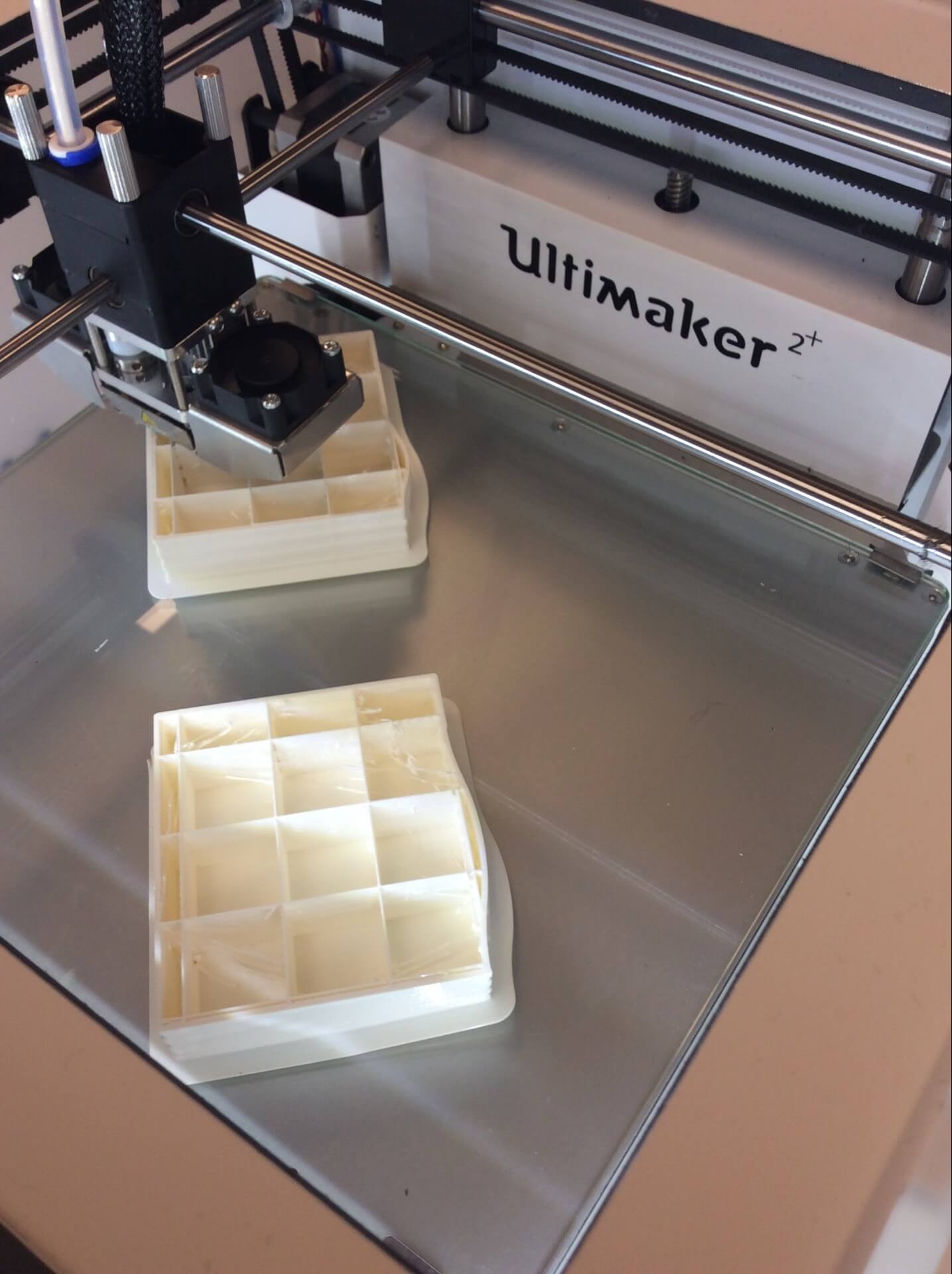

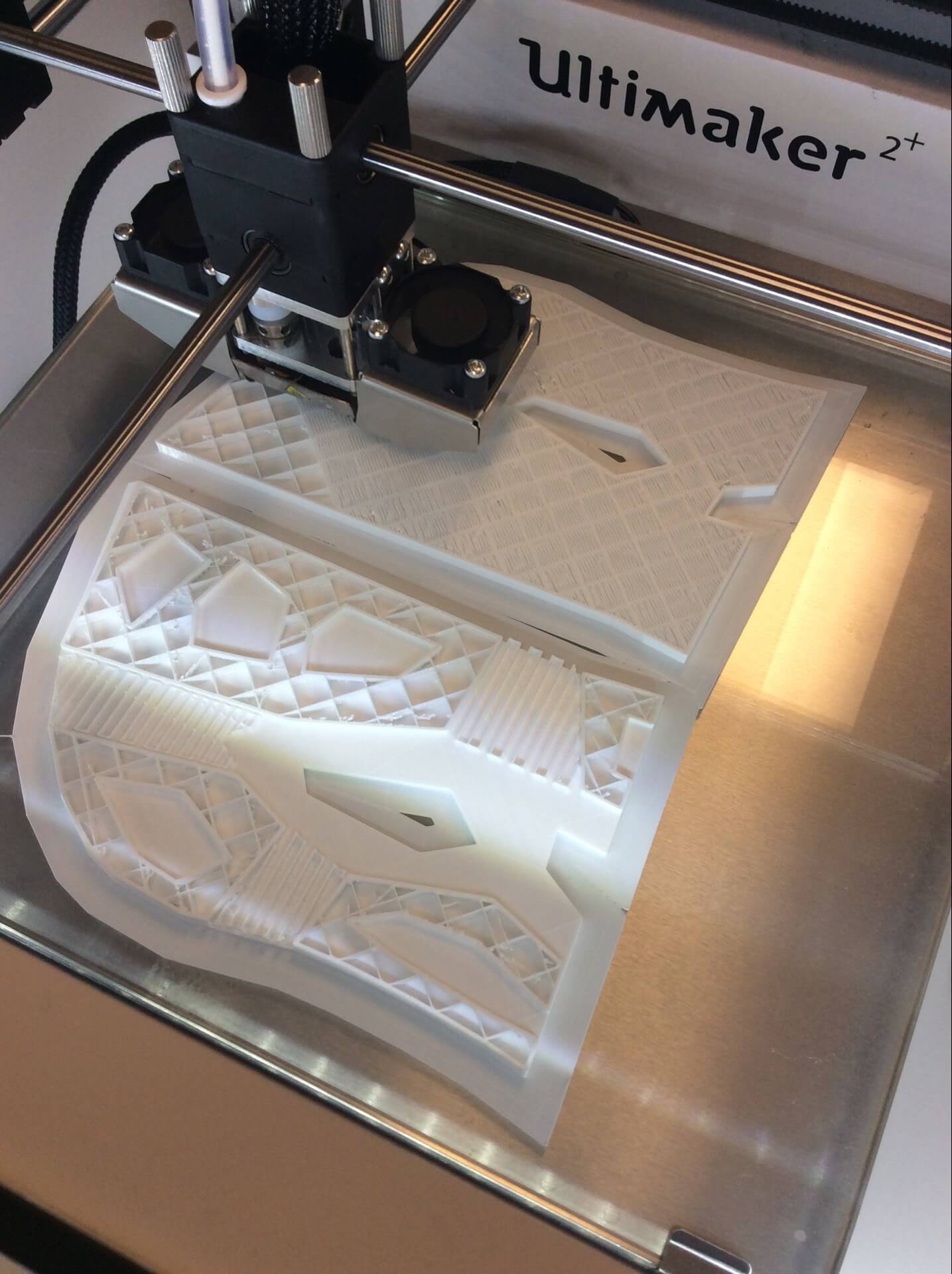

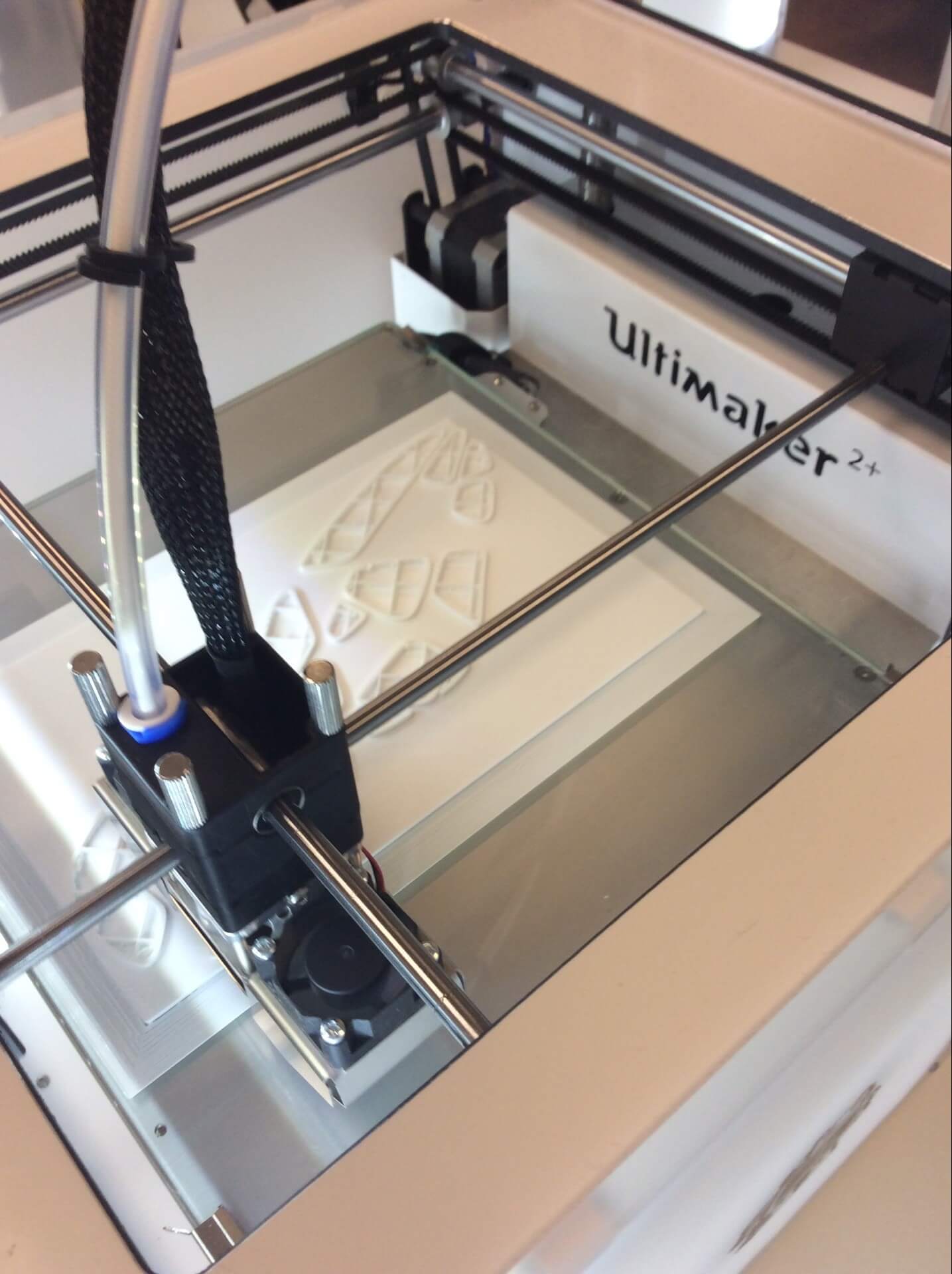

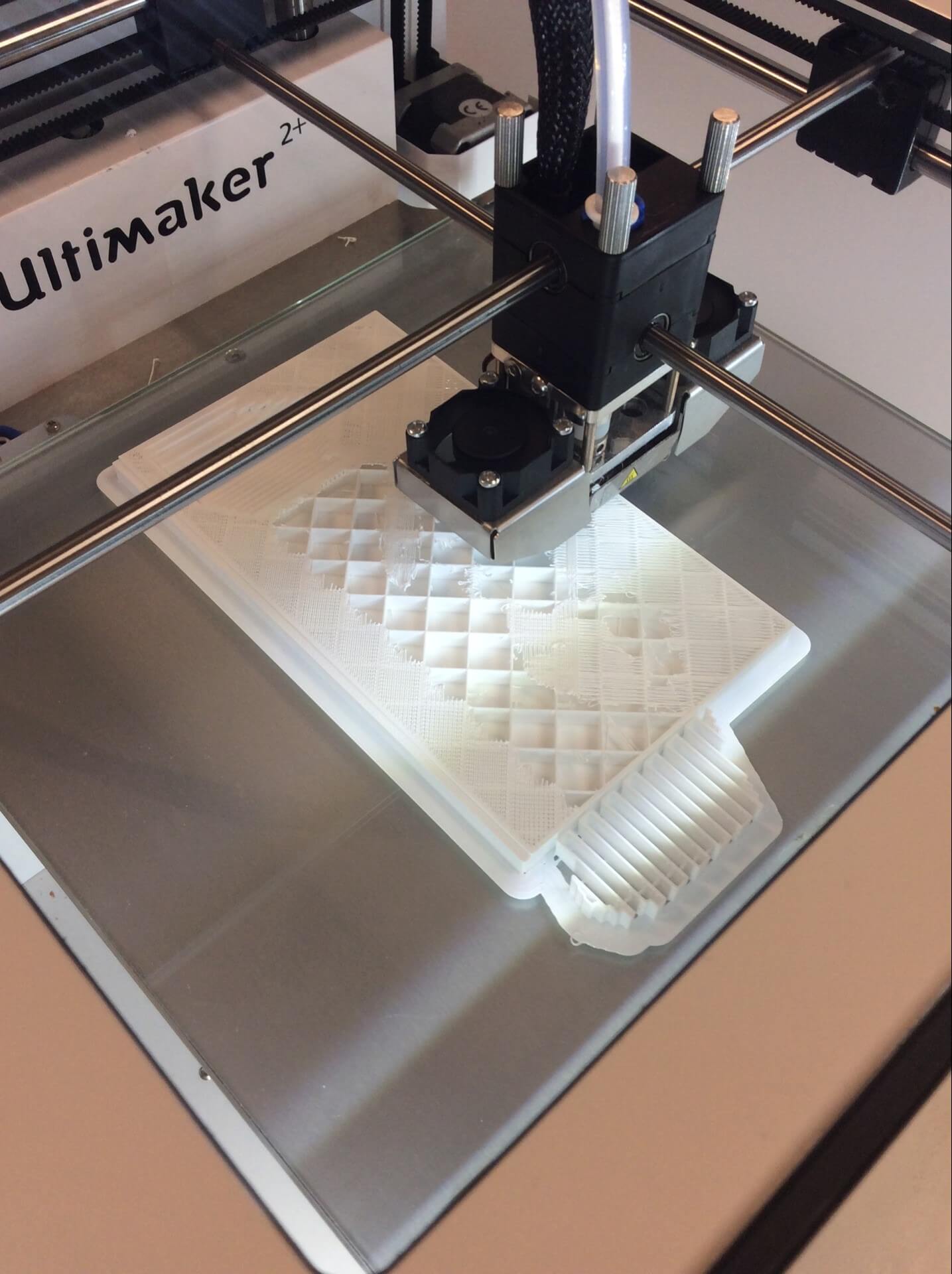

Reese is currently a freshman here at Illinois studying Agricultural and Biological Engineering. Reese came into the MakerLab to print a micro quadcopter frame. A micro quad copter is a mini helicopter that has four rotor blades instead of the typical one. His plan was to make a small enough quadcopter that he could fly it indoors once winter came. Reese found the design for the quadcopter online to print but hopes to design his own frame the next time he comes into print. Once the design was printed, Reese added batteries and controls to the frame so that his quadcopter can actually fly!

Find out about all our makers at http://makerlab.illinois.edu/category/makers/. If you have made something at the lab, and would like to share with us to feature on the blog, drop us a line at http://makerlab.illinois.edu/contact.