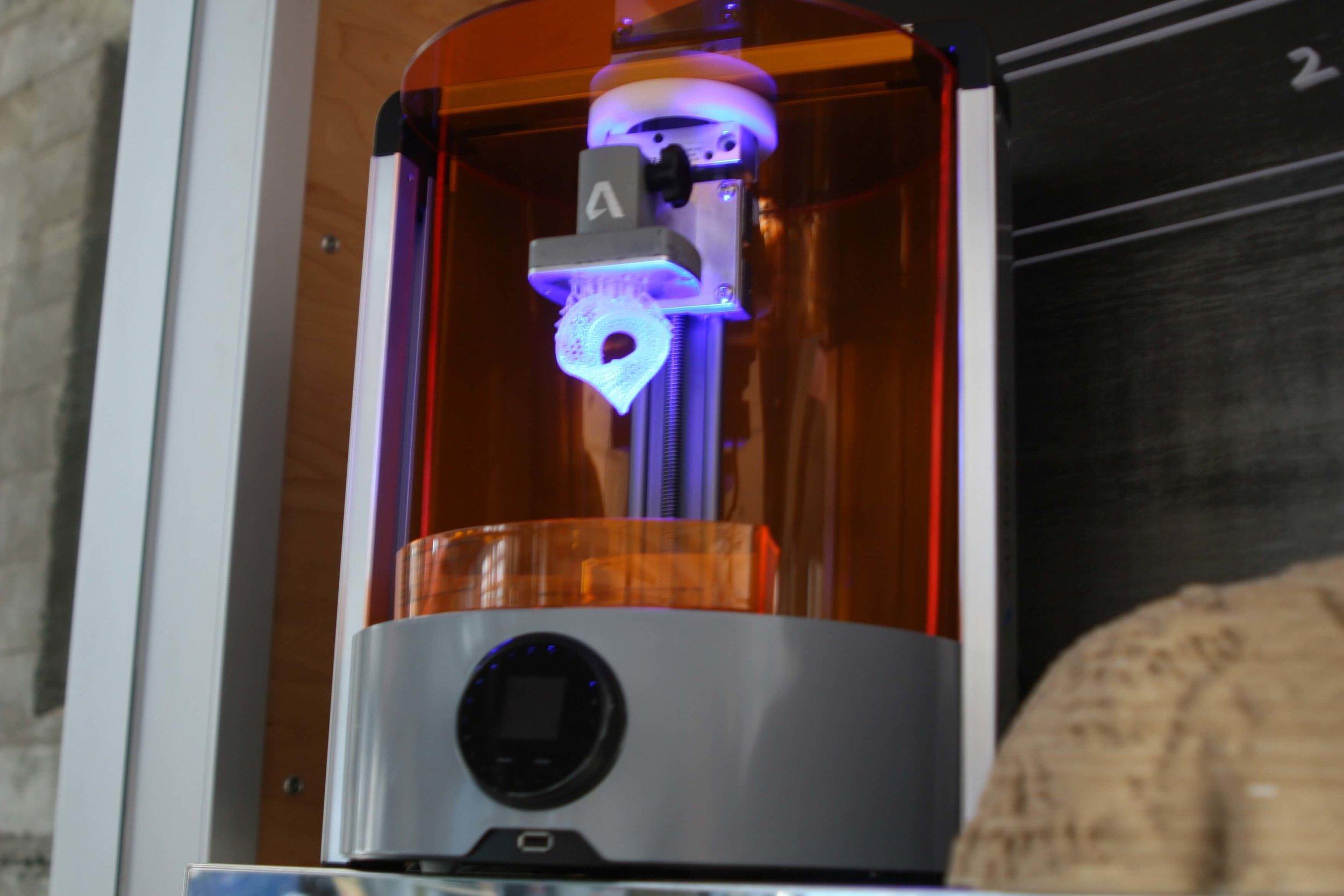

3D Printing Conference a Big Success

/Earlier this month, the Illinois MakerLab successfully hosted its first 3D Printing Conference, with over forty faculty and students in attendance from across our campus. The conference began with Dean Brown delivering a set of opening remarks and was followed by interesting presentations by John Hornick [Finnegan & Associates], Jeff Smith [Autodesk], Ed Hmurovic [Ultimaker], and Mark Cotteleer [Deloitte]. These presentations were followed by an invigorating discussion panel headed by three Illinois faculty [Jeff Ginger, James Leake, and David Weightman]. This conference discussed several new advances in the 3D Printing domain, including the news that Hewlett-Packard plans to release a 3D Printer in the next two years, the development of liquid metal as a new 3D Printing material and that the University of Louisville has announced that they plan to print a human heart by 2023!

We hope to host a similar conference in the Fall 2016. Stay tuned for details!