A 3D Printed Skyrim Digital Book!

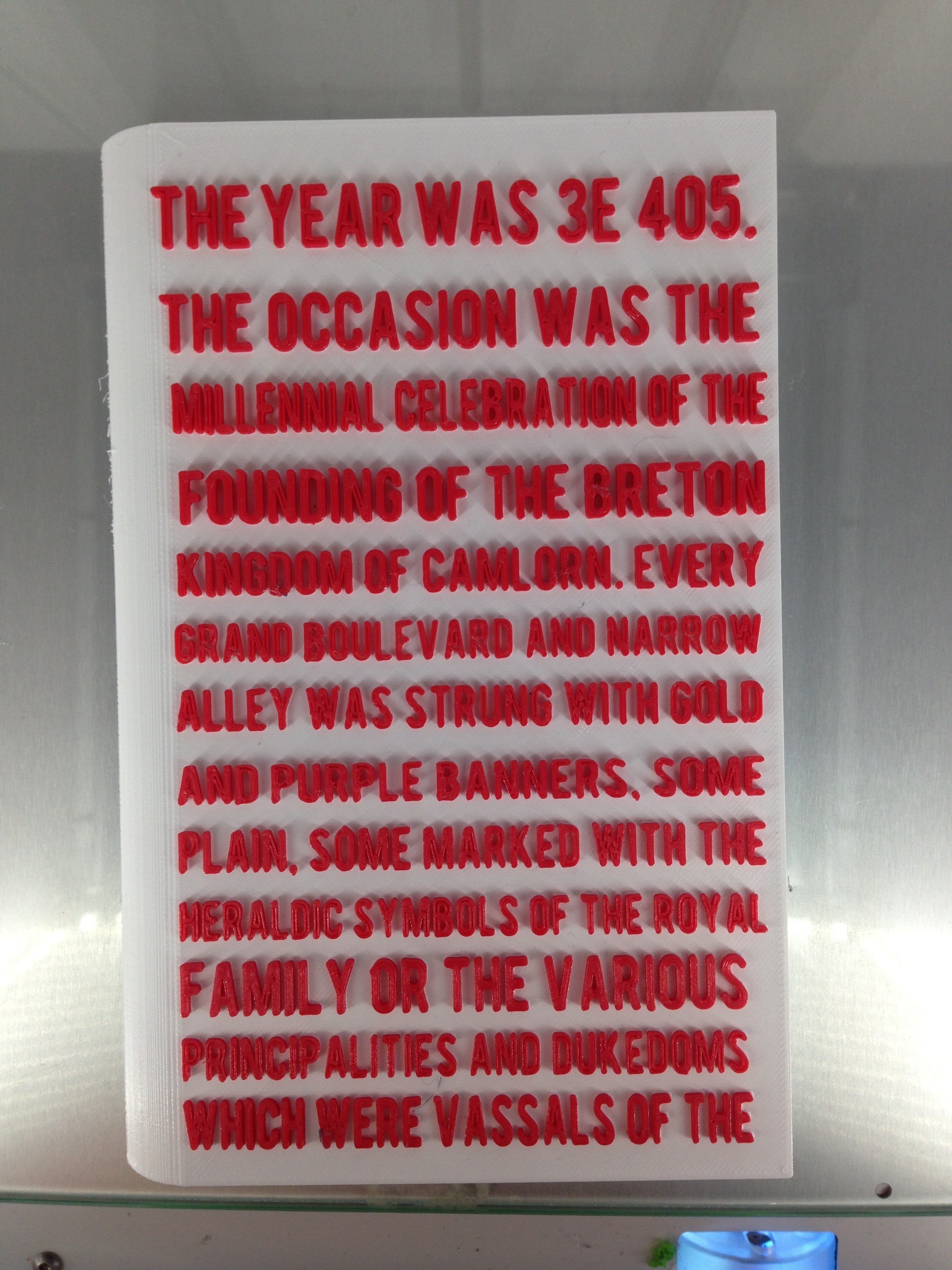

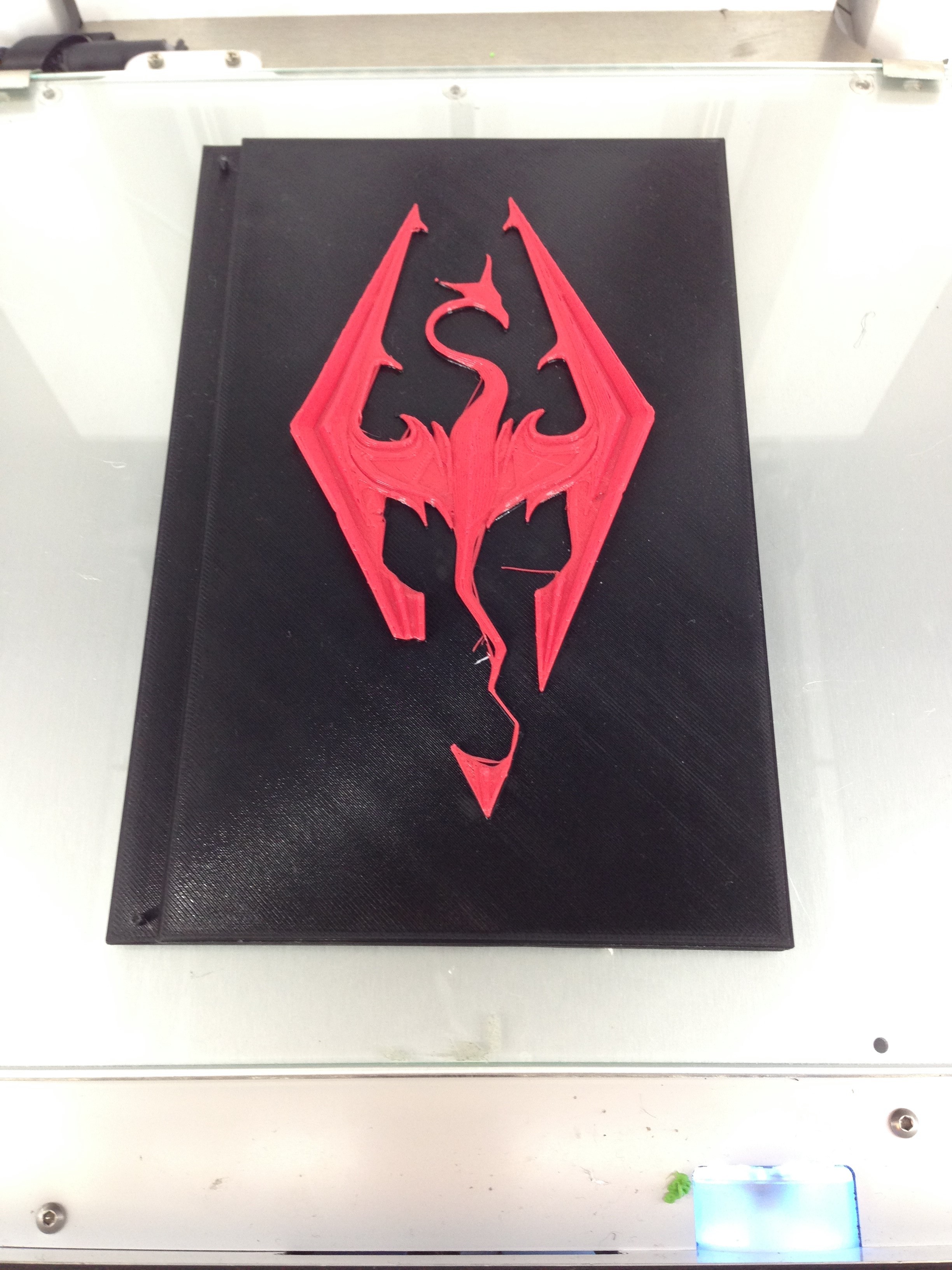

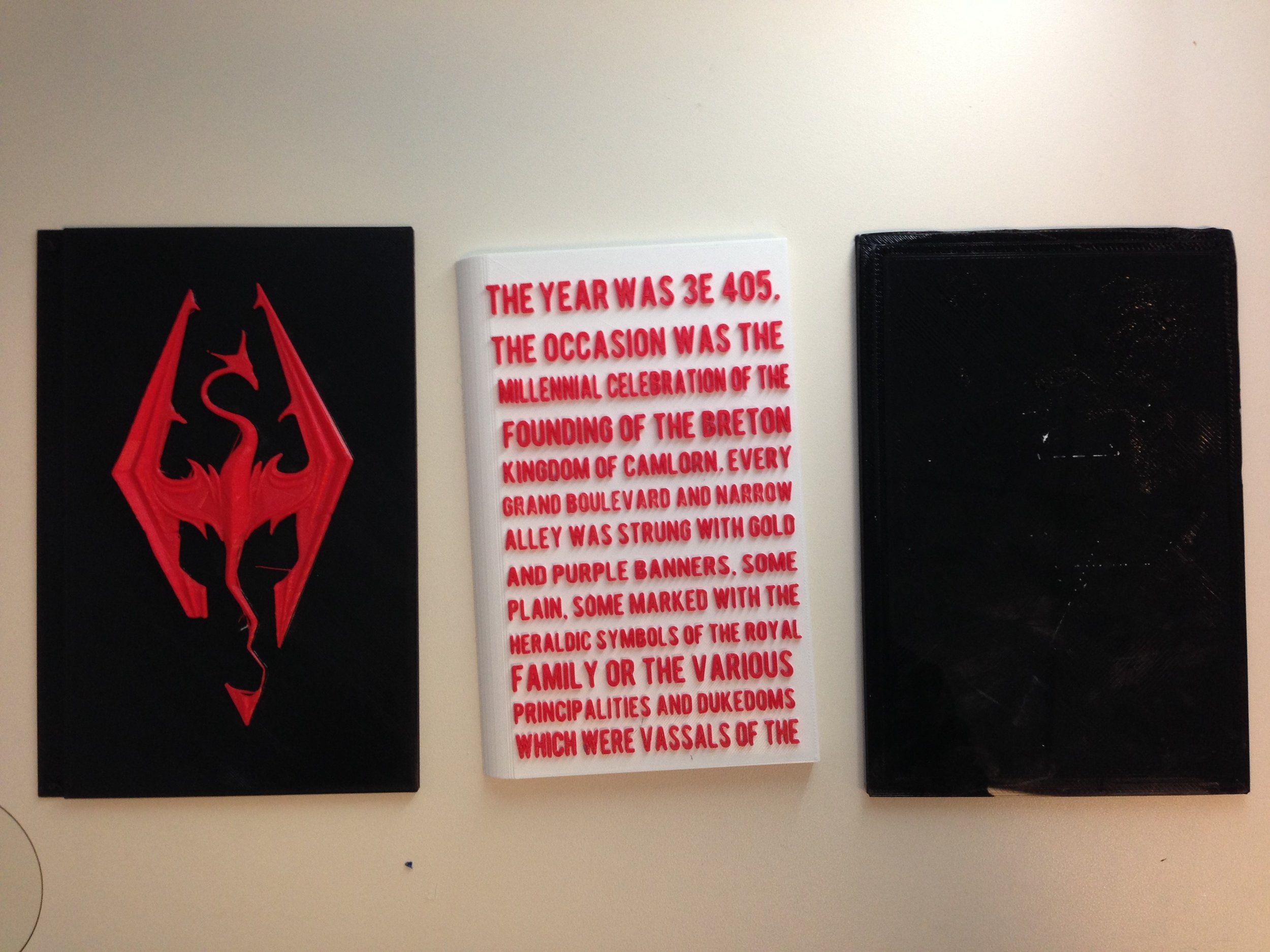

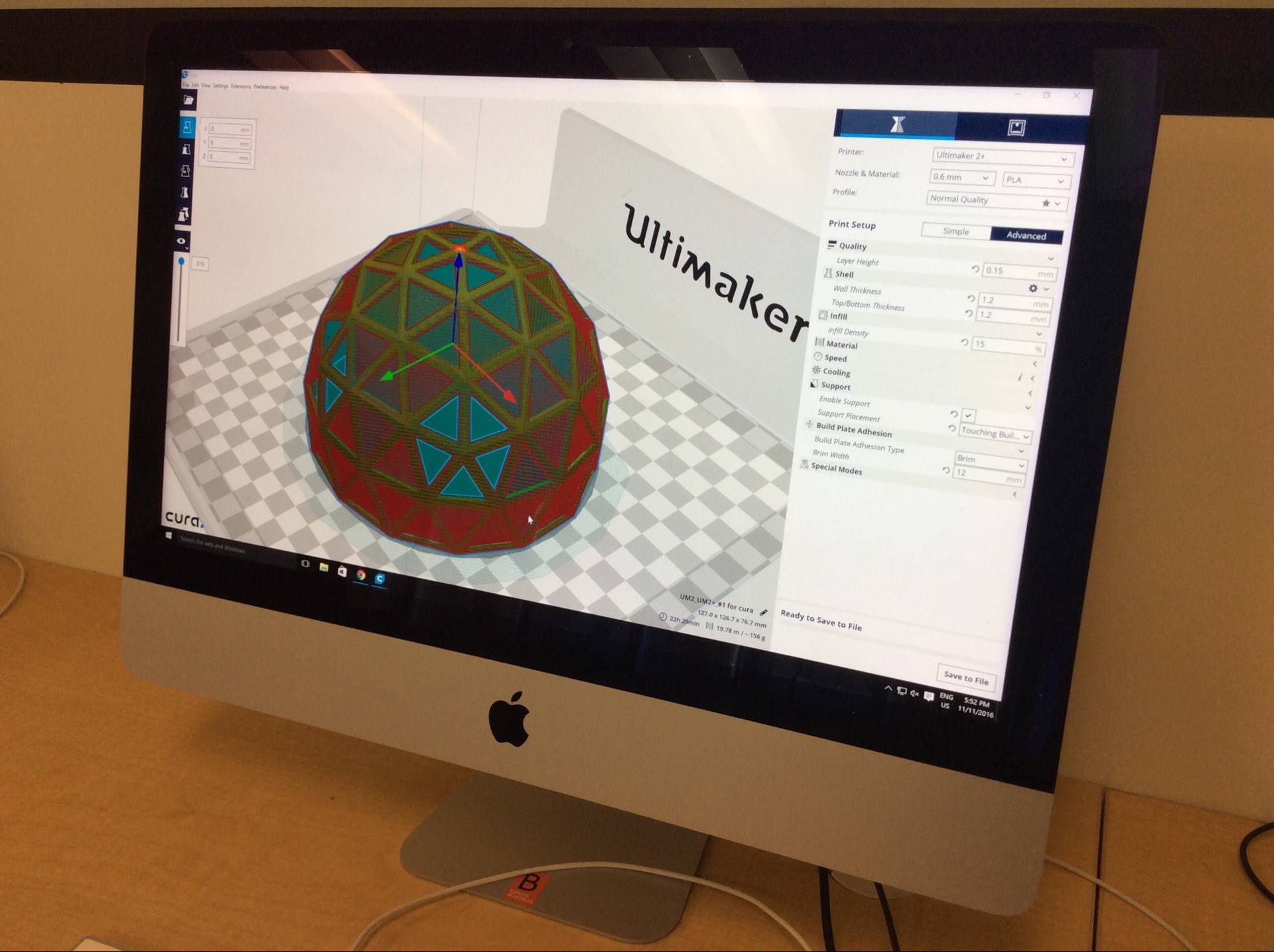

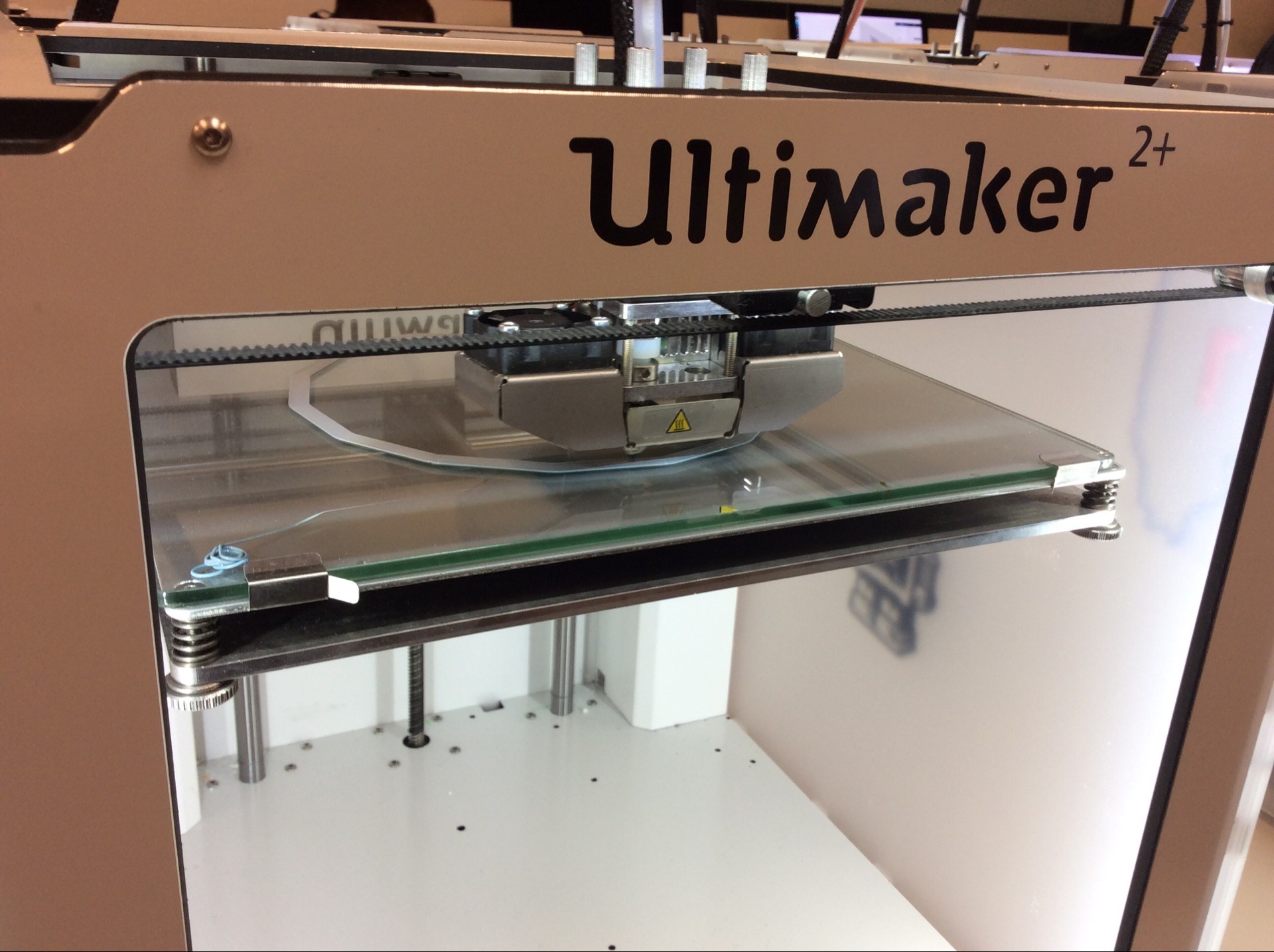

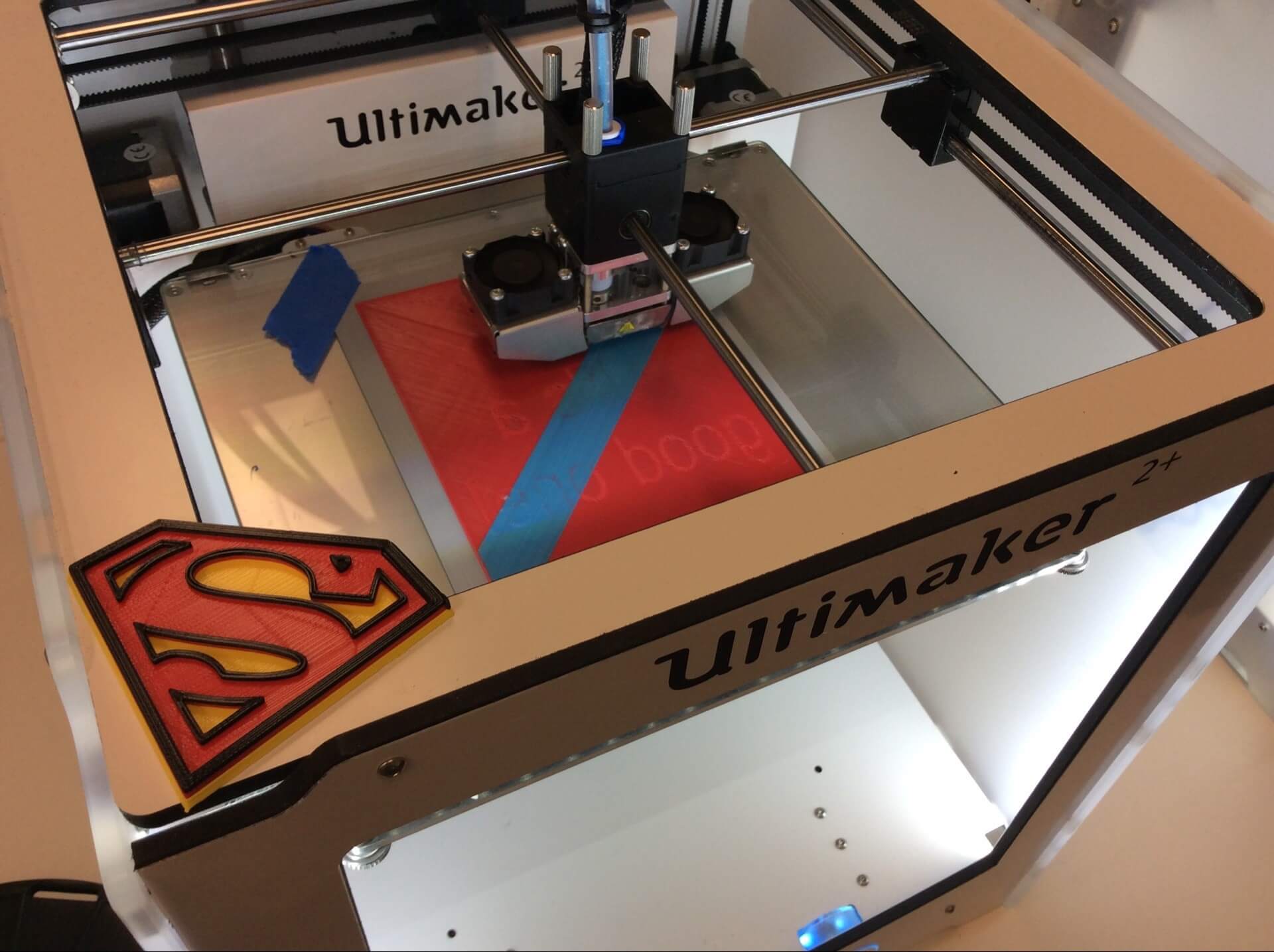

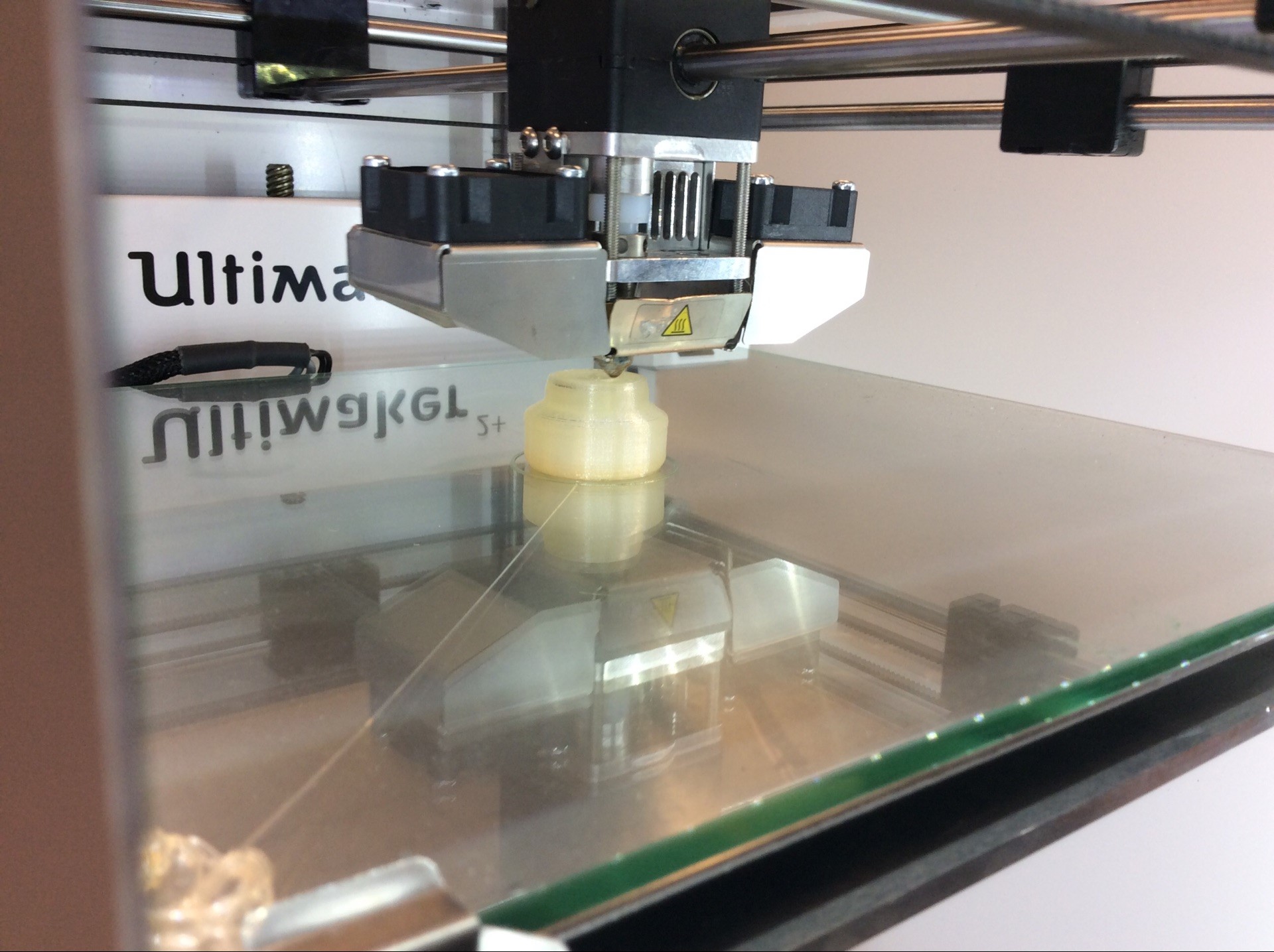

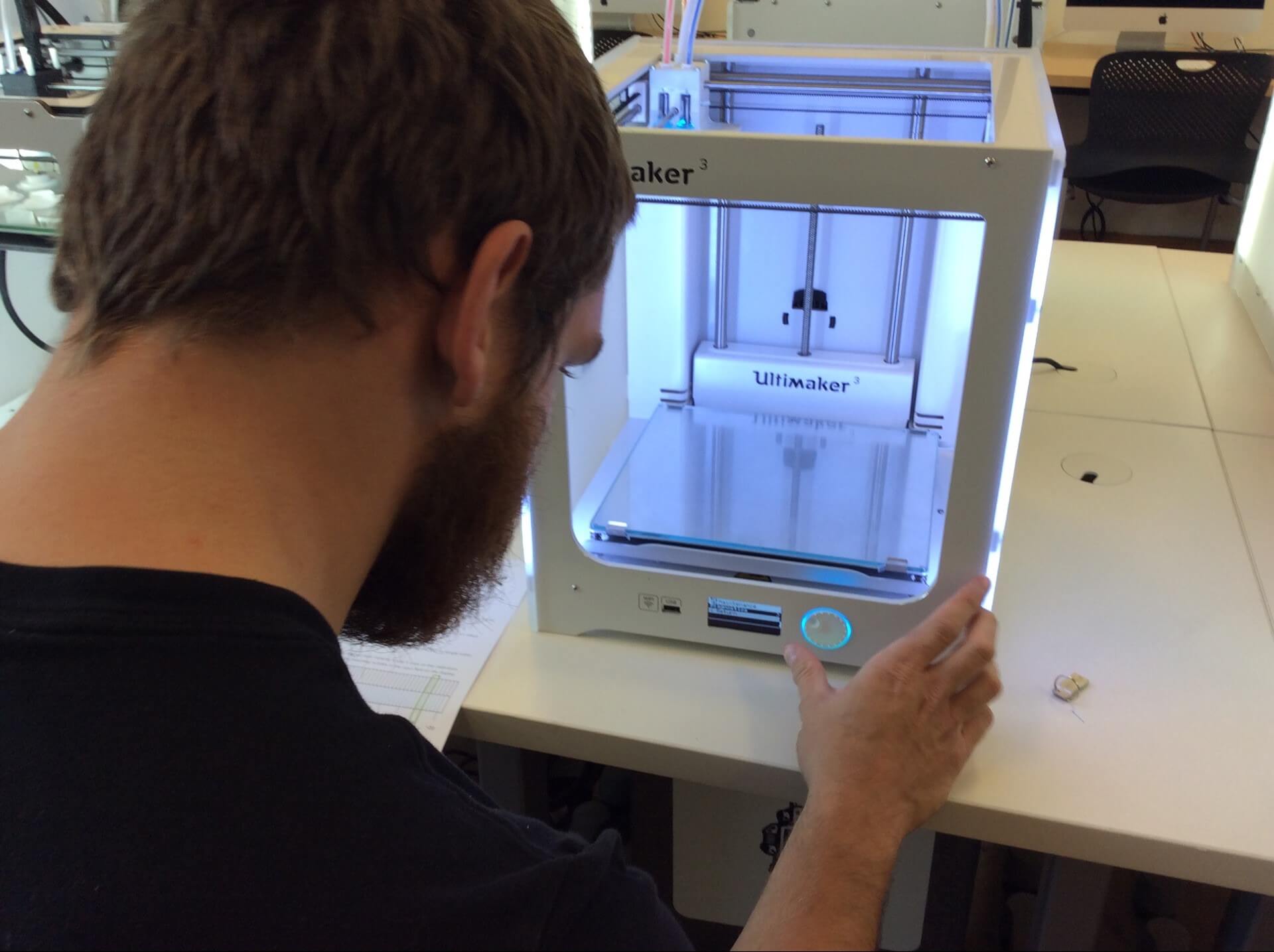

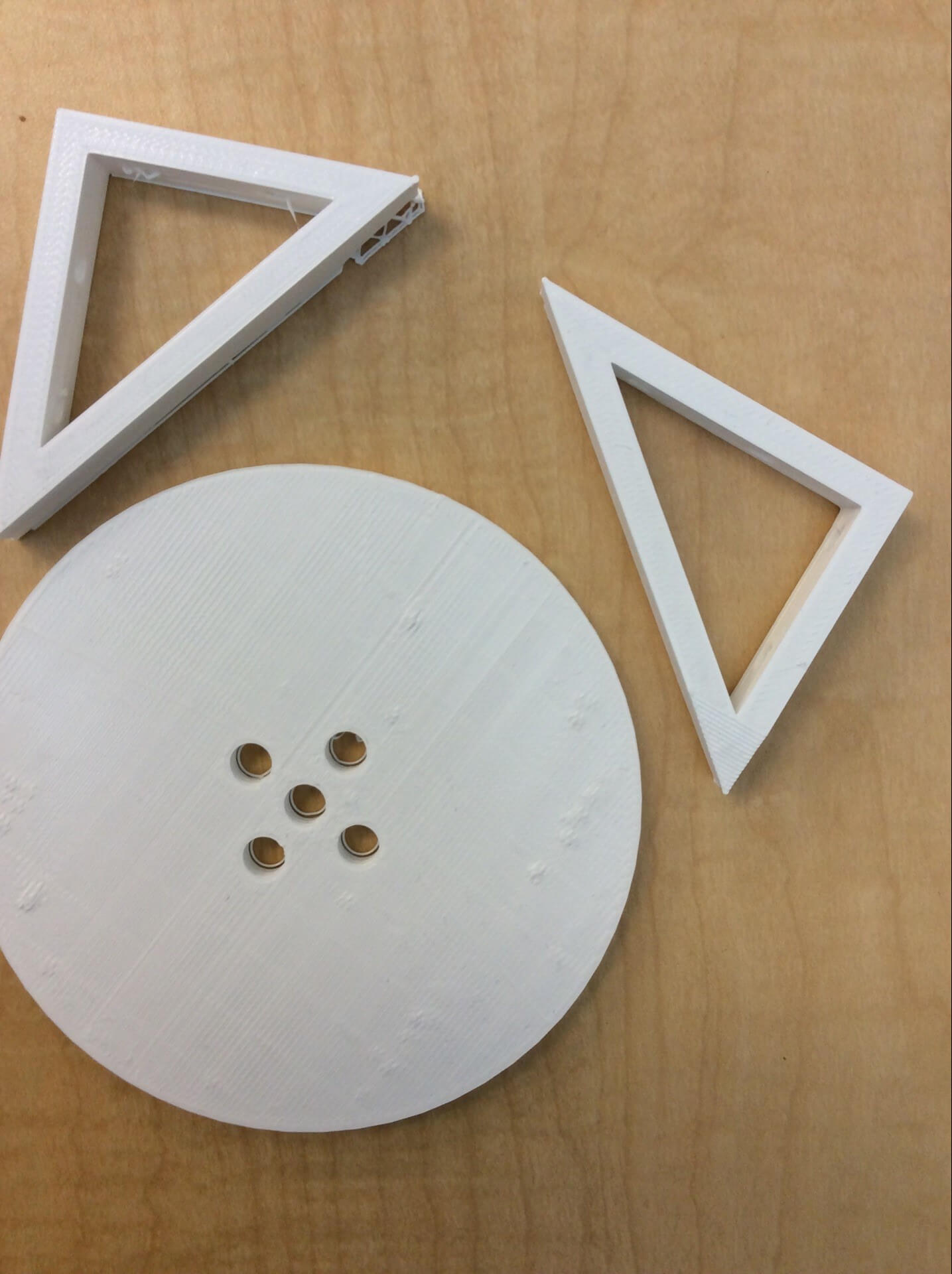

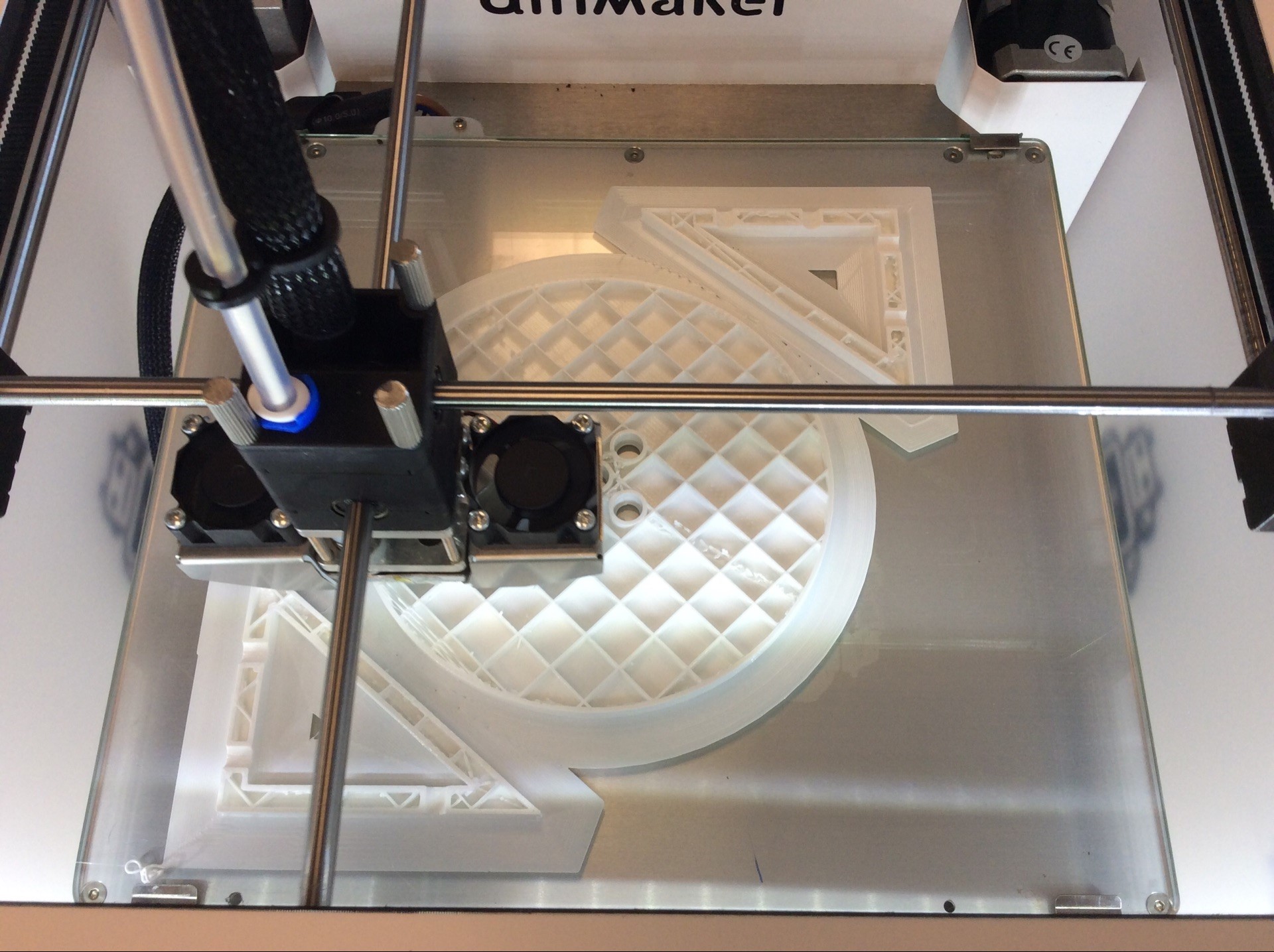

/"The year was 3E 405." This is the first line in a digital book found in the video game, Skyrim. Now, it is not only found digitally but physically as well. This book was 3D printed for maker Justin Williams. Our Guru, Jim, decided to make good use of our Ultimaker 3 and print the book using two colors. The two different colors allowed the text to stand out on the page. The hardest part when dealing with this project was making the spine of the book. The goal was to make the spine flexible, allowing it to open and close like a real book. In order to do this, we used a printing filament known as Ninja Flex. We have had trouble in the past getting the flexible filaments printing correctly. However, Jim, found that the best way to improve the print quality was slowing down the print speed to 1/5th of the normal speed. The final result looks amazing!