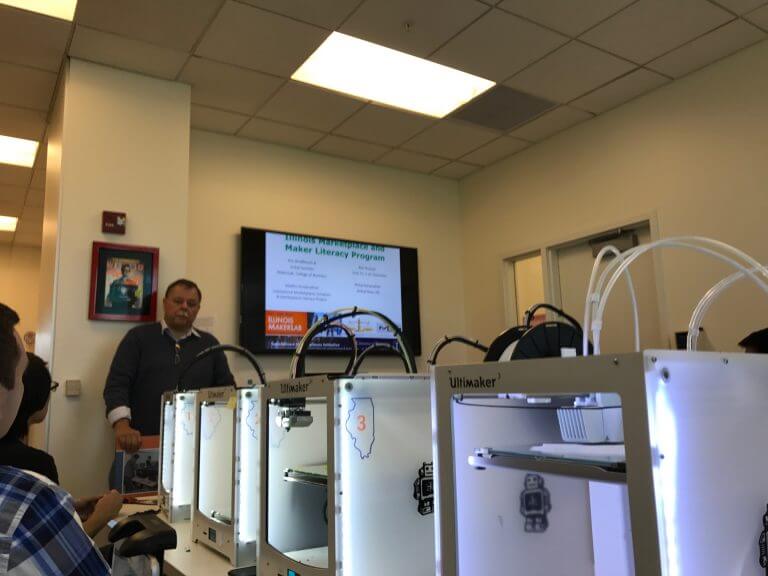

The MakerLab was honored to be invited by Infosys Foundation USA to participate in a talk on how 3D printing can be used to enhance and improve learning. Infosys Foundation USA is a "non-profit organization passionate about bridging the digital divide in America*." Infosys works to breach this gap of knowledge between people in America by sharing stories about why people create the things that they do. These stories are posted on Infosys twitter using the hashtag WhyIMake. Not only does Infosys shares stories of what people make but the organization has also set up an information chat where companies come to talk about how their technology and how it will change America for better. Any one who wishes to learn more about a company or a particular technology can participate in the chat. Illinois MakerLab directors were invited to such a chat to talk about 3D printing's impact on learning within a school environment. The chat consisted of 4 questions. The answers below are a general summary of what was discussed during the chat. More detailed answers can be found at https://storify.com/InfyFoundation/3dprinting.

*Taken from Infosys Foundation USA's mission statement.

Q1: Do you own a #3DPrinter in your classroom or have access to one? If not, do you see one in your future? Why?

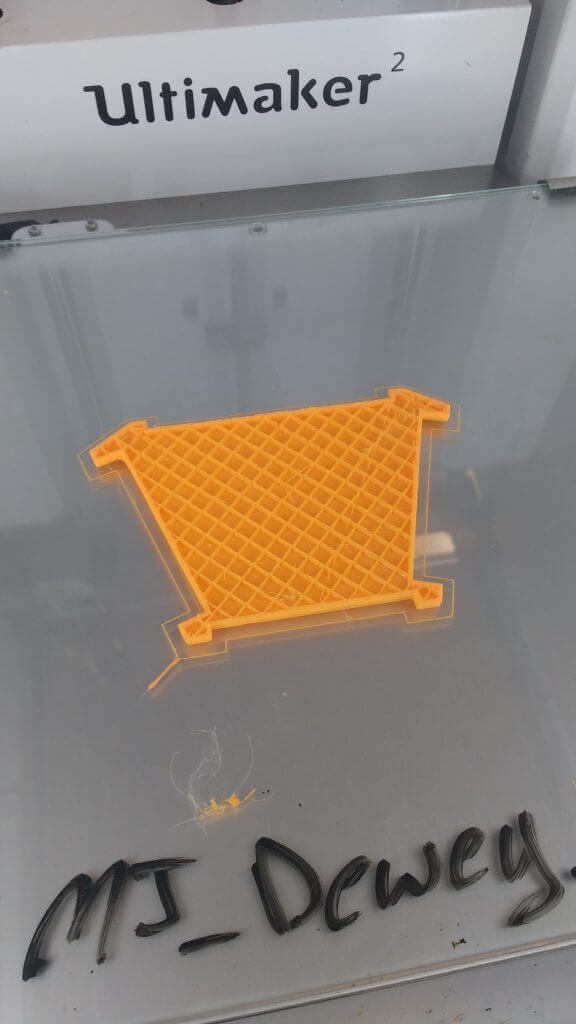

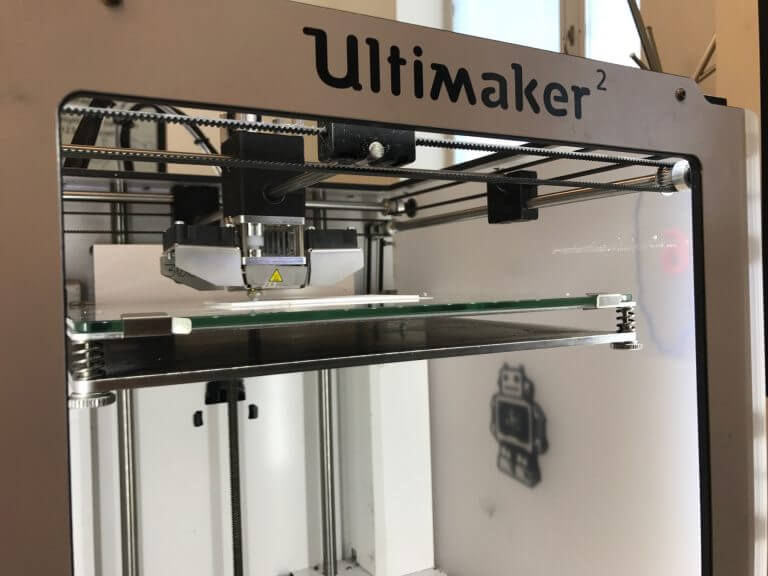

We found that the majority of people may not have access to a 3D printer within their school but had access to one at a local library or community center. However, it does seems like schools are looking at adding some 3D printers as they could be used for example in geometry class as one participant pointed out. As schools work on getting 3D printers, be sure to check out your local library to try out 3D printing for yourself!

Q2: How do you see #3Dprinting as relevant to what you teach and your own personal background?

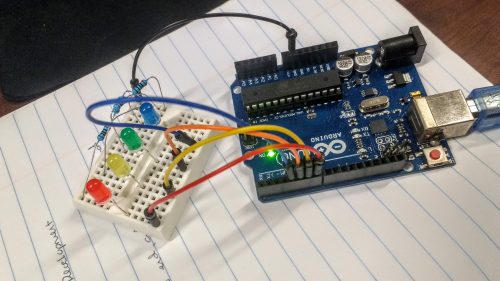

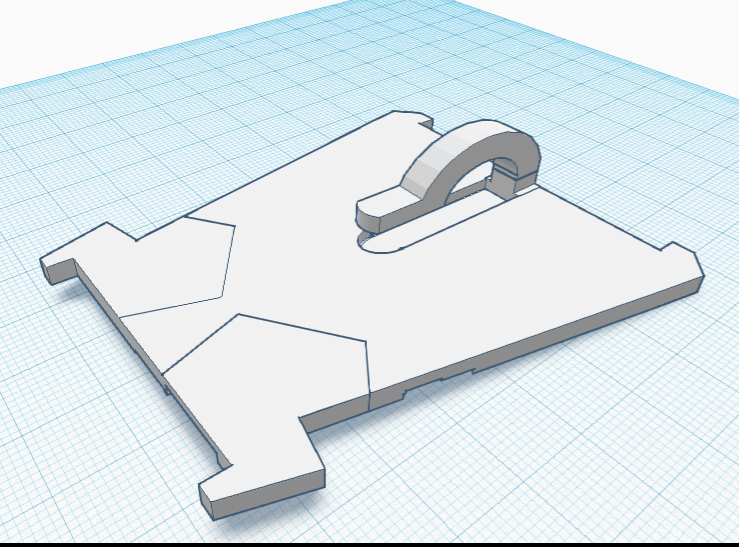

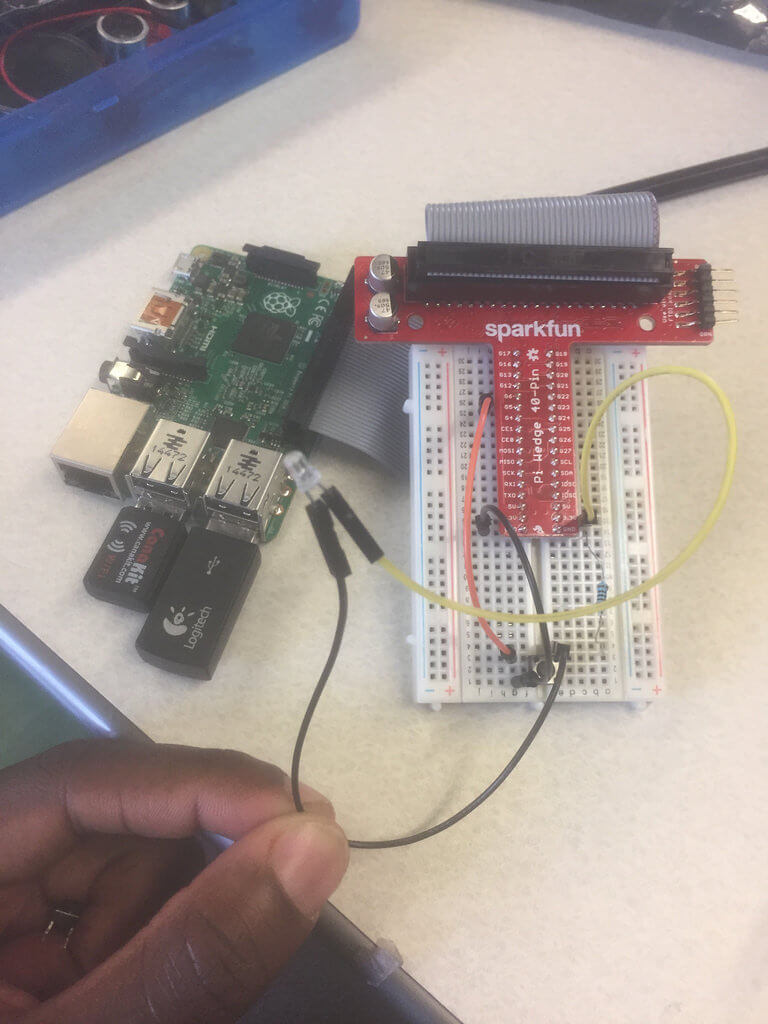

One participant responded to this question with "it will be one of the essential skills in future, just like Microsoft Office. I just think we should learn and know how to use it." We completely agree! The MakerLab offers 2 different undergraduate classes involving 3D printing as well as offering numerous workshops. Other participants used CAD (digital design) regularly in the classes that they teach. These participants found it very helpful to be able to turn their digitally created designs into physical objects!

Q3: What are tangible ways you use #3Dprinting to teach concepts?

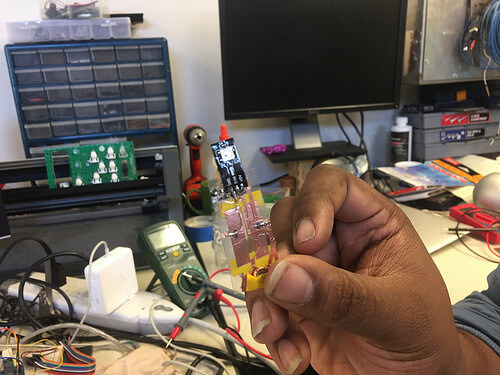

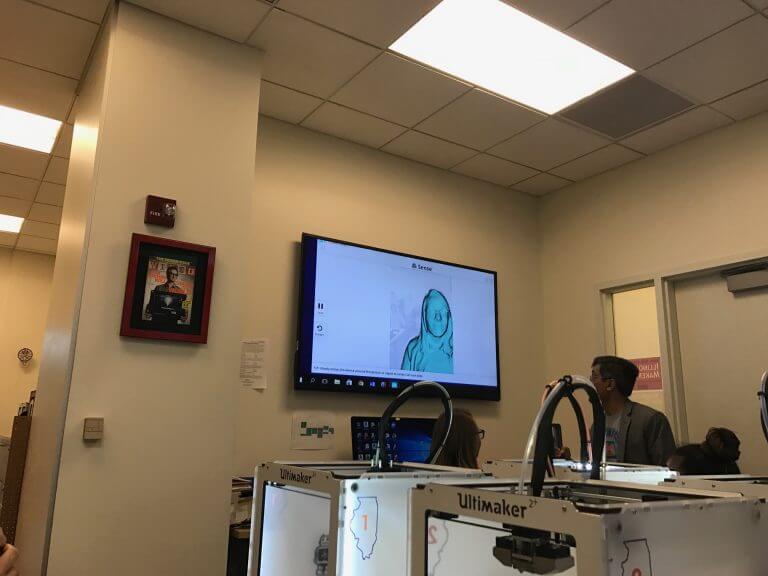

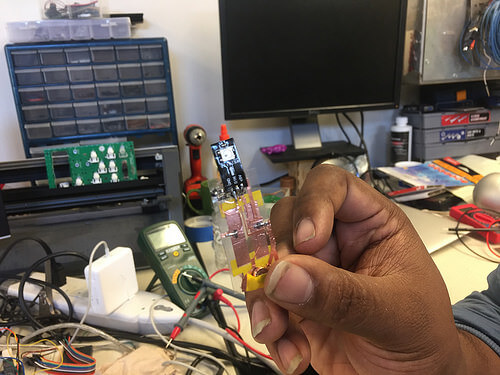

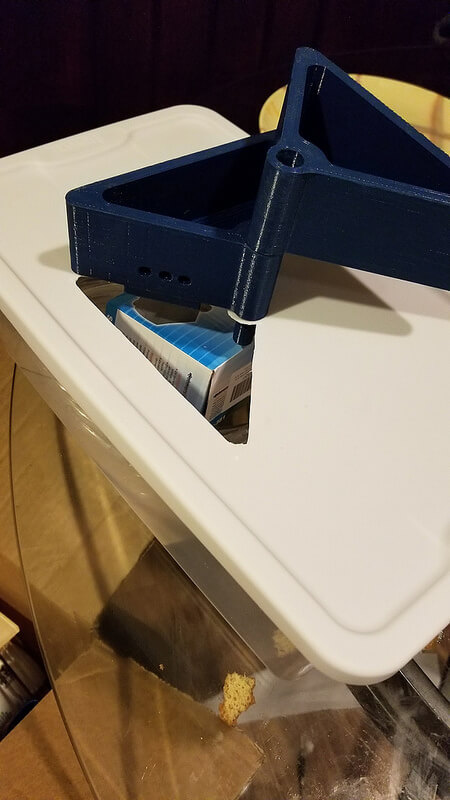

3D printers lead to easy access in the need of manufacturing on demand. 3D printing allows to repair damaged goods at a much lower cost! Another option is to use the 3D scanners to create replicas of objects one may need. We like to always remember maker Arielle Rausin using a 3D scanner to scan and then print her own wheelchair racing gloves.

Q4: What kind of support would be most useful for you? Training, curricula, projects?

Participants hope to have easier access to the hardware and software involved with 3D printing. These participants want to be able to easily teach what they know of 3D printing to others. Others find that knowing the differences between all the different 3D printers and filaments available in the world. Knowing these facts will help to make sure that your print turns out successful on the first try! Education Closet provides a great list of resources to use and consider when 3D printing.